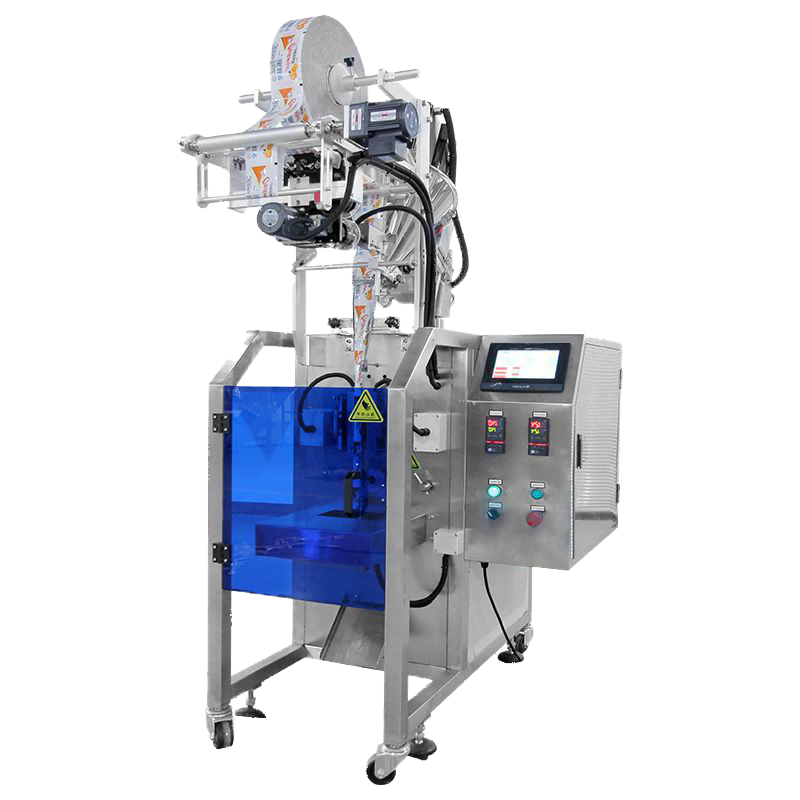

Fully automatic powder vertical packaging machine

1. It can realize fast and continuous packaging operations, greatly improve production efficiency and shorten production cycle.

2. The entire packaging process is automatically completed by the PLC control system, from automatic feeding and metering, filling and filling, packaging sealing to coding output and other integrated operations.

3. According to different product requirements, you can choose a variety of bag types such as three-side seal, four-side seal, back seal, etc., and you can also achieve customized packaging size and shape.

4. The use of advanced energy-saving technology and equipment reduces energy consumption and saves production costs while ensuring production efficiency, which meets the requirements of sustainable development of modern enterprises.

5. It supports data communication with the host computer, can collect and record various data in the packaging process in real time, and provide valuable production information for enterprises.

The fully automatic powder vertical packaging machine is an advanced equipment widely used in the field of powder product packaging. It integrates automation technology, precision metering system and diversified packaging functions, providing reliable, efficient and high-quality packaging services for many industries.

Equipped with advanced sensors and intelligent metering control modules, whether it is fine food additive powder or relatively coarse chemical raw material powder, it can achieve accurate metering within a strict error range.

It is not significantly affected by factors such as ambient temperature, humidity, and fluctuations in powder physical properties, and it always maintains high-precision measurement levels during long-term operation.

It uses high-quality motors, reducers, transmission chains and other key components, has good heat dissipation performance and overload protection function, and can operate stably under long-term and high-intensity working environment

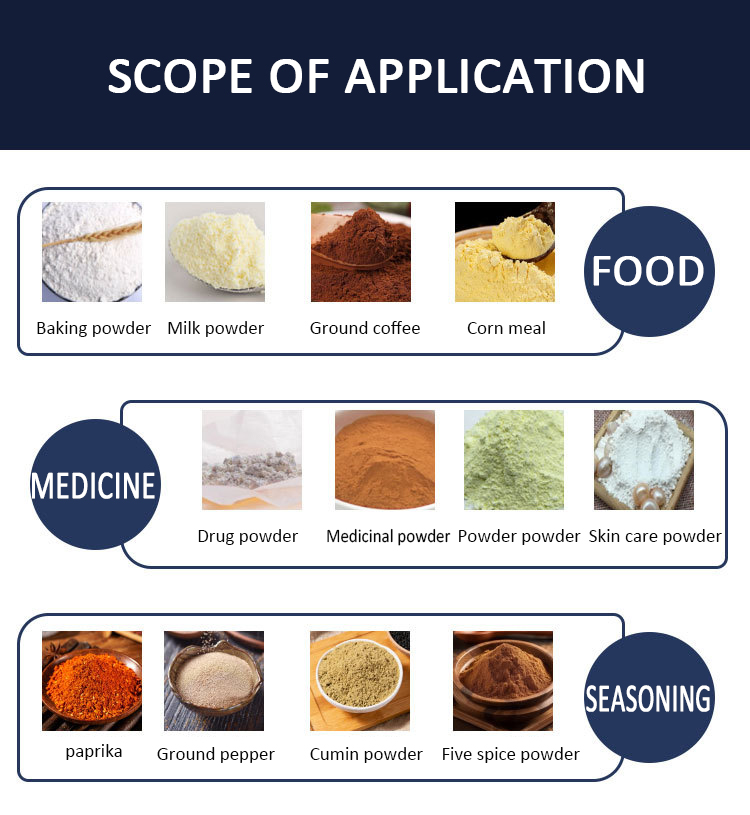

It has strong versatility and can adapt to the packaging needs of powders with different properties, particle sizes and fluidity. Whether it is milk powder and coffee powder with good fluidity, or chemical powder with poor fluidity and easy to agglomerate, or pharmaceutical powder with special physical and chemical properties, etc.

The equipment has a reasonable structure design, compact layout of mechanical parts, and is easy to disassemble and install. The main parts are made of high-quality materials with good wear resistance, corrosion resistance and fatigue resistance, effectively reducing the probability of component wear and damage.

During the packaging design process, the utilization rate of packaging materials is fully considered. By optimizing the packaging process and control procedures, the amount of packaging materials used is accurately calculated to minimize waste.

A series of advanced energy-saving technologies and optimized power system design are adopted to reduce energy consumption during equipment operation.