Feeding multifunctional packaging machine

1. It integrates multiple packaging functions such as feeding, metering, filling, sealing, labeling, etc.

2. It can adapt to the packaging requirements of different products by simply adjusting parameters or replacing some components.

3. It is equipped with an advanced feeding system, which usually adopts high-precision sensors and intelligent controllers to accurately control the feeding speed and feeding amount of materials.

4. It supports multiple metering methods such as weight metering and volume metering. For granular products with uniform density, volume metering can be used for rapid packaging.

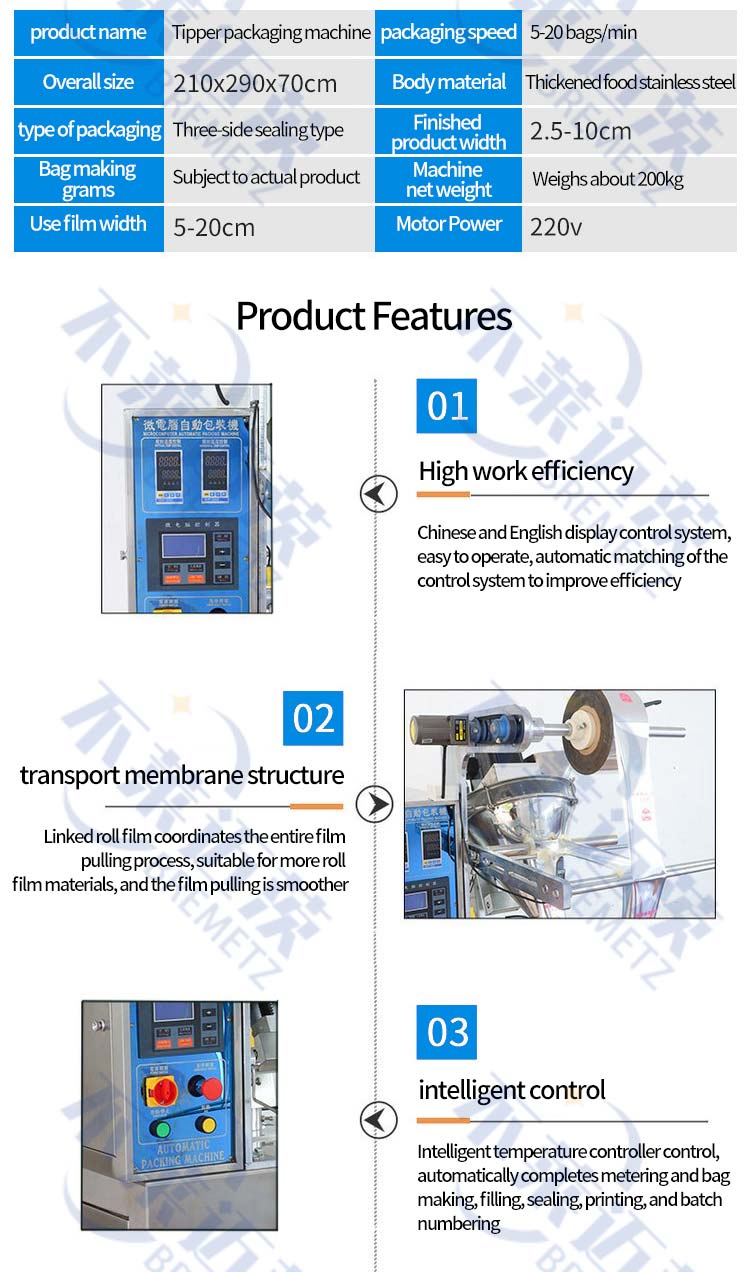

5. In the sealing process, advanced heat sealing, pressure sealing and other technologies are adopted, and the sealing parameters can be accurately adjusted according to different packaging materials and packaging forms.

The feeding multifunctional packaging machine is a modern packaging equipment that integrates advanced technology and innovative design concepts, aiming to provide efficient, accurate and diversified packaging solutions for various industries.

Use high-precision screw feeder or vibrating feeder, which can be selected according to the characteristics of the material. The feeder is made of high-quality stainless steel, with good corrosion resistance and wear resistance, ensuring long-term stable operation.

The weighing sensor has high sensitivity and high precision, and can quickly and accurately sense the weight change of the material. The metering control module processes and analyzes the received weight signal in real time according to the preset packaging weight parameters.

The packaging forming part includes various types of bag makers, such as three-side sealing bag makers, four-side sealing bag makers, back-sealing bag makers, etc., which can produce packaging bags of corresponding shapes according to different packaging design requirements.

The label roll holder can be installed with label rolls of different specifications for easy label replacement. The label conveying mechanism adopts a precise transmission device, which can smoothly convey the label from the roll to the labeling head.

PLC has powerful computing and processing capabilities and rich control functions, and can accurately control and coordinate the management of each link such as feeding, metering, packaging molding, sealing, labeling, etc.

The machine body adopts a solid metal frame structure, usually made of high-quality carbon steel or stainless steel, and has good rigidity and stability after fine welding and processing.