Blister Packaging Machine

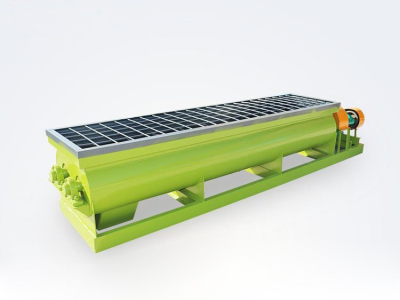

1. It can quickly and accurately complete the entire process from material forming to product packaging, greatly improving production efficiency and shortening production cycles.

2. It usually integrates multiple processes such as material conveying, heating forming, filling, heat sealing, cutting and cutting to form a complete automated production process.

3. The advanced control system enables the machine to automatically adjust various operations such as temperature, speed, pressure, etc. according to preset parameters to ensure the consistent quality of each packaging unit.

4. Through mature heat sealing technology, the formed blister and the back plate form a tight sealing structure, effectively isolating the outside air, moisture and microorganisms.

5. The independent cavity design of the blister can effectively disperse and resist external impact, even if it encounters bumps during logistics transportation.

Blister packaging machine is an advanced packaging equipment widely used in many industries such as medicine, food, daily chemicals, electronics, etc. It mainly heats and softens plastic sheets to form blisters, then places the product in the blister, and then heat-seals it with the covering material to achieve sealed packaging of the product.

Advanced heating control system can realize precise control of the temperature of heating plate or heating roller, and the error can be controlled within ±1℃, ensuring that the plastic sheet is heated evenly during the molding process, thus ensuring the stable molding quality and high dimensional accuracy of the blister.

The material conveying system adopts advanced sensors and automatic control technology, which can achieve accurate positioning and conveying of products and blisters.

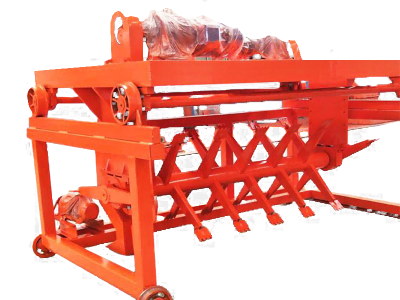

Model:bremetz-D500

Tumtable shape:Round or rectangular

Power Supply:220v 50-60HZ

Platen area:0*500MM

Power:2KW

Machine volume :500*710*1400MM

Bakelite module:Two/three

Weight:80KG

It can realize packaging of various blister shapes and sizes, such as round, square, rectangular, special-shaped, etc., to meet the packaging needs of different products.