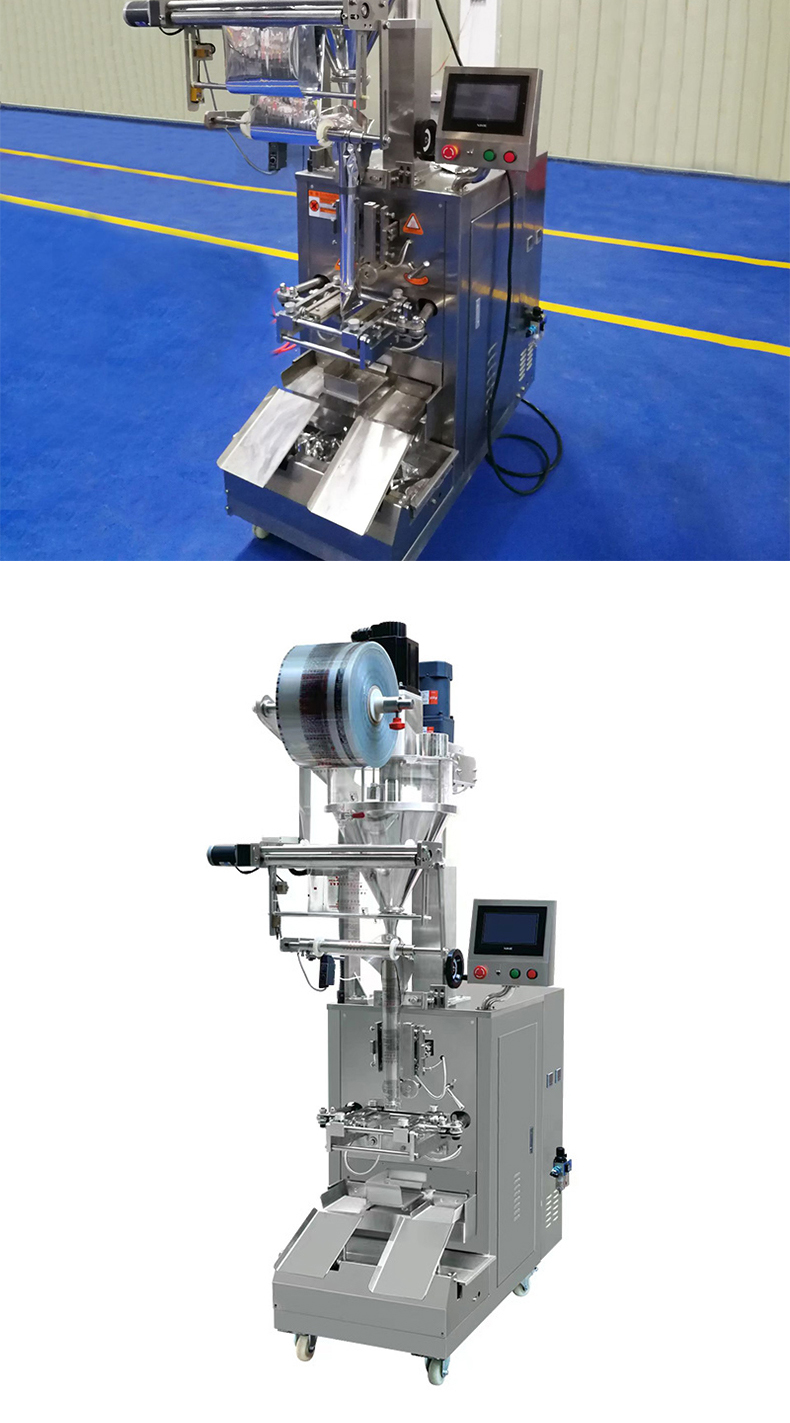

Automatic bag granule packing machine

1. Efficient packaging speed: It has a high packaging speed and can be adjusted according to different granular material characteristics and packaging specifications.

2. High-precision measurement system: Equipped with advanced measurement devices, high measurement accuracy can be guaranteed whether using weighing measurement, volume measurement or counting measurement.

3. High-quality sealing and filling effect: In the sealing process, a firm and tight seal can be achieved. Advanced sealing technology is used to effectively prevent particle leakage and the entry of outside air and moisture, ensuring the stability and stability of the product during storage and transportation. quality.

4. Support for multiple packaging forms: It can be adapted to a variety of packaging forms, and companies can flexibly choose packaging forms based on product characteristics and market demand.

5. Simple operation interface: Equipped with an intuitive and friendly human-machine interface, usually in the form of a touch screen. Operators can easily get started without complicated training, and packaging parameters can be conveniently set on the interface.

6. Significant cost-effectiveness: An automatic granule bagging and packaging machine can replace multiple traditional manual packaging positions or simple semi-automatic packaging equipment.

Automatic bag granule packing machine is an automatic packaging equipment designed for granule materials. It integrates advanced mechanical design, metering technology, automatic control system and packaging technology, and can efficiently and accurately complete the bagging and packaging of granule materials. It is widely used in many industries such as food, medicine, chemical industry, agriculture, etc.

Product parameter:

Bag size:Width :30-130 mm Length:30-170 mm

Productive capacity:30-60 bags/min

Measuring range:3-150ml (can be customized)

Gross power:220V/50HZ1.4KW

Machine weight:300KG

External dimension:(L x W x H) 900x1100x1900 mm

Sealing die,Horizontal seal vertical seal independent temperature control is convenient to adjust the diversification of sealing patterns.

Ribbon coding machine or inkjet printer can be installed,Very convenient to print the production date.(can be customized 6*7MM large grain)

Replaceable pneumatic main engine,More energy saving Low failure rate High safety maintenance Simple maintenance cost low.

Multi-direction adjusting screw bucket,Easy to remove material, easy to clean and not easy to dust.

Stepper motor control blanking,Adjustable cutting grams precision metering motor long life and high safety.

High-quality packaging is ensured in the filling and sealing process. The particles can be evenly filled into the bag, and the seal is firm and tight, effectively preventing the leakage of particles and the entry of outside air and moisture, ensuring the stability and quality of the product during storage and transportation, extending the shelf life of the product, and at the same time improving the appearance of the product and enhancing consumers' trust in the product.

It can handle granular materials of various shapes, sizes, densities, fluidity and viscosity. By adjusting equipment parameters and configuring special devices, it can handle particles with special properties such as easy to absorb moisture, easy to agglomerate, strong electrostatic adsorption, etc., so that it can be widely used in many industries such as food, medicine, chemical industry, agriculture, etc., to meet the needs of different industries for granule packaging.

We continue to pay attention to the development of industry technology, provide users with technical upgrade services for equipment in a timely manner, and continuously improve the performance, function and intelligence level of equipment through software updates, hardware improvements, etc., so that the equipment always maintains advanced performance and meets the growing production needs and market competition requirements of users.