Automatic bag sewing machine

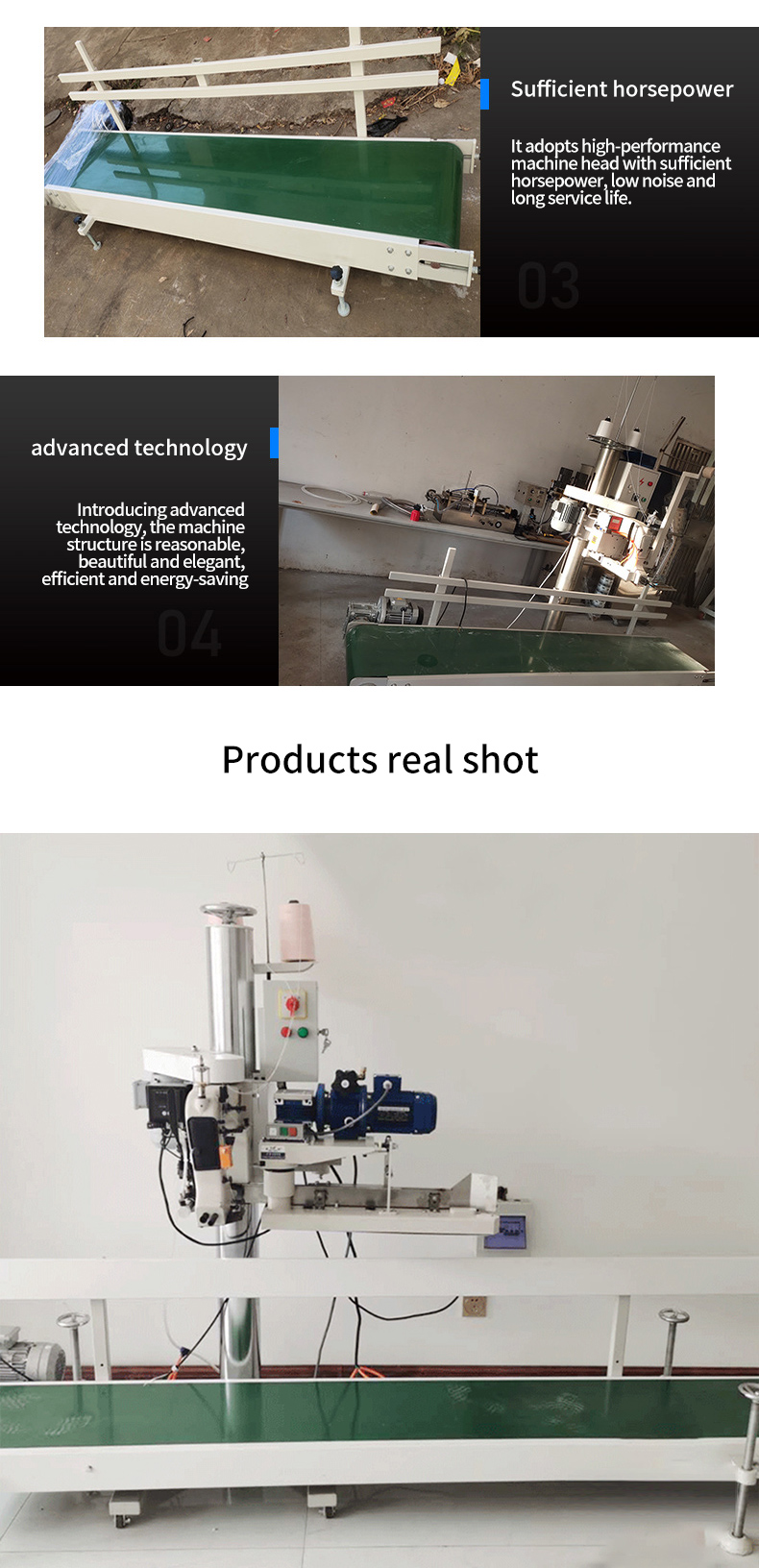

1. With excellent sewing speed, it can complete the sealing and sewing of a large number of bags in a short time.

2. It can realize automatic continuous sewing operation without frequent manual intervention. The equipment can automatically transport bags, position, sew and output.

3. It has a high-precision stitch adjustment function and can accurately set the stitch length according to the material, thickness and packaging requirements of different bags. The stitch length error can be controlled within a very small range.

4. The use of advanced sewing technology and high-quality sewing components can form neat, tight and stable sewing stitches.

5. It has good adaptability to various common bag materials, such as paper bags, plastic bags, woven bags, etc.

6. The operator can easily adjust multiple parameters such as sewing speed, stitch length, thread tension, etc. to meet the sewing requirements of bags of different specifications and types.

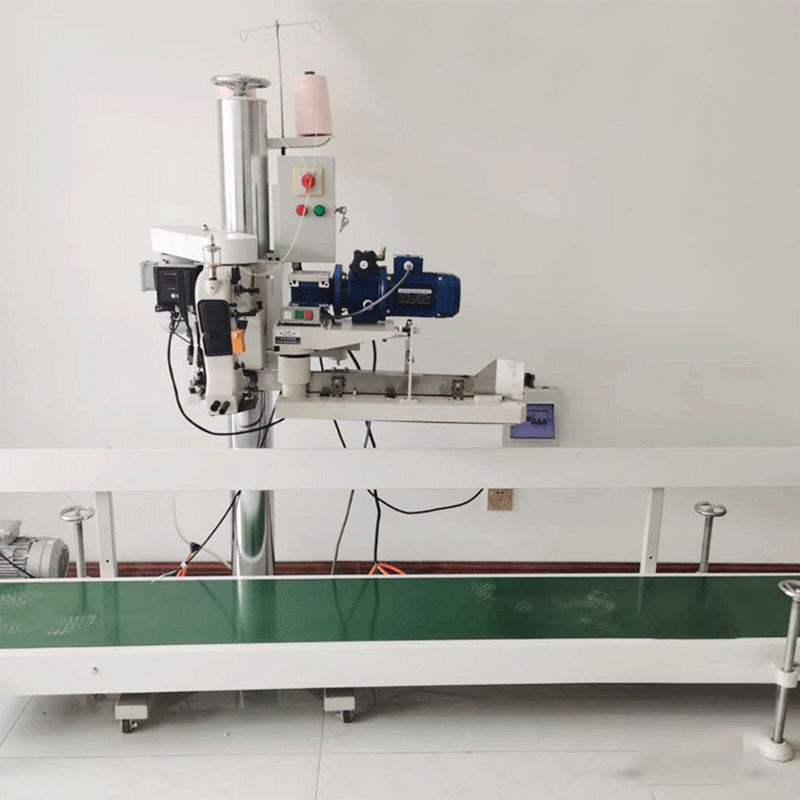

The automatic bag sewing machine is an efficient automation equipment widely used in the packaging industry. It is mainly used for sealing and sewing operations of various bags. It can sew the bag mouth accurately and quickly, significantly improving the efficiency and quality of packaging operations.

packaging speed:9 meters/minute 200-400 bags/hour

sewing height:400-900mm, adjustable

Sewing bag weight:10-50kg

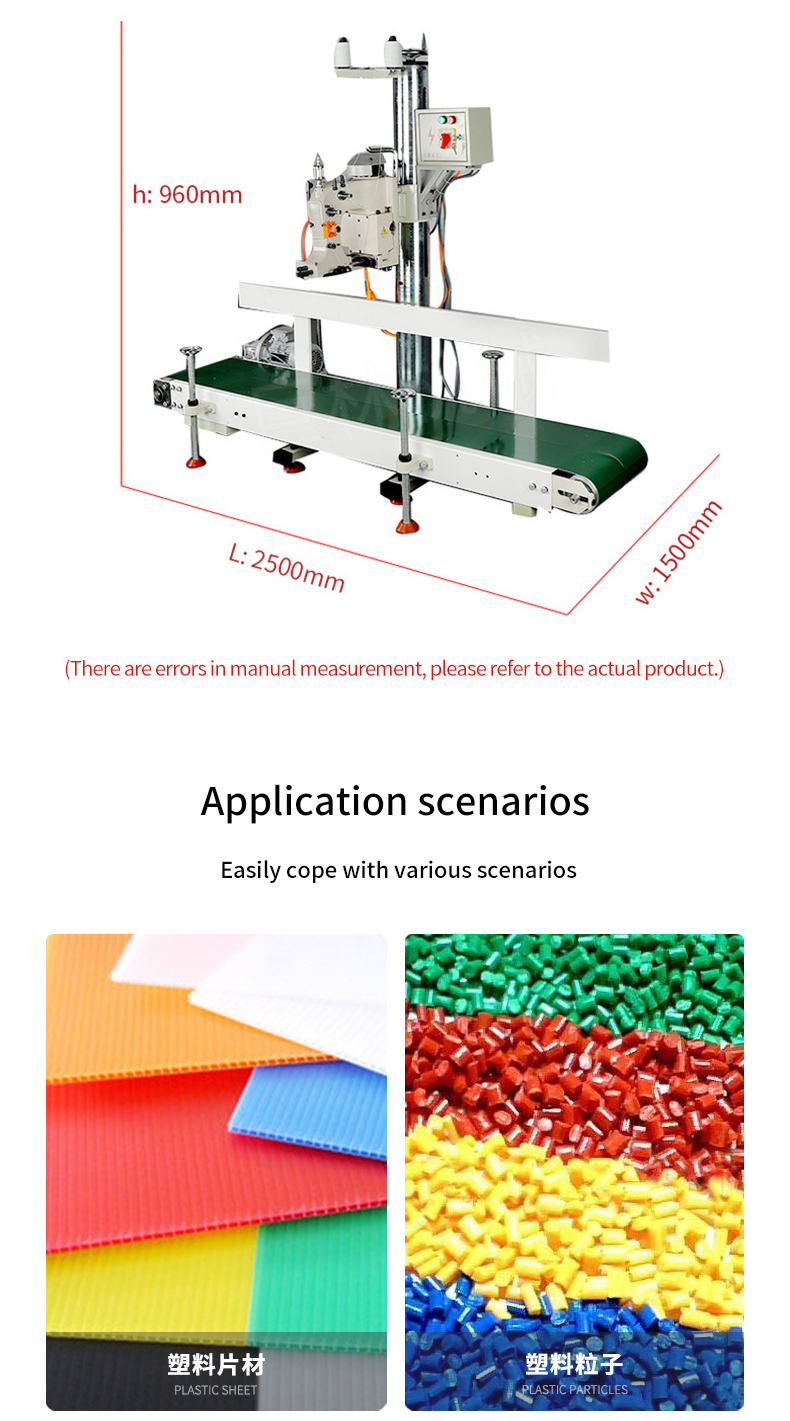

Dimensions:2500mm*1500mm*960mm

motor:Conveyor 550w bag sewing machine 370w

gross weight:About 240kg

Belt height from ground:320mm Conveyor belt width: 400mm

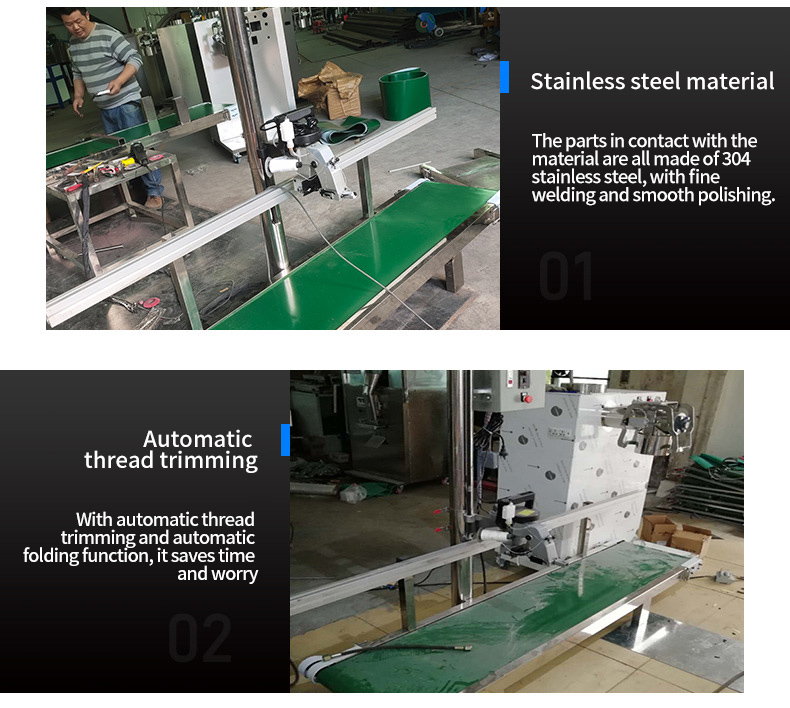

Made of solid metal materials, such as high-quality carbon steel or aluminum alloy, through precision welding and processing technology. It has good stability and anti-deformation ability, providing a reliable installation foundation for other components.

Through advanced control systems and high-precision mechanical components, parameters such as sewing stitch length and thread tension can be accurately controlled to make the sewing stitches even and tight, the bag opening is firmly sewn, and the leakage of items in the bag is effectively prevented.

It has good adaptability to bags of various materials, such as paper bags, plastic bags, woven bags, etc., as well as bags of different specifications and shapes. Simply adjust the equipment parameters to easily cope with various packaging tasks.

Equipped with intelligent human-machine interface and programmable logic controller, operators can easily set parameters, control equipment and diagnose faults. The operation interface is simple and intuitive, and can be mastered without complex training.

The use of high-quality materials and advanced manufacturing technology ensures that the equipment has stable and reliable performance during long-term high-intensity operation.