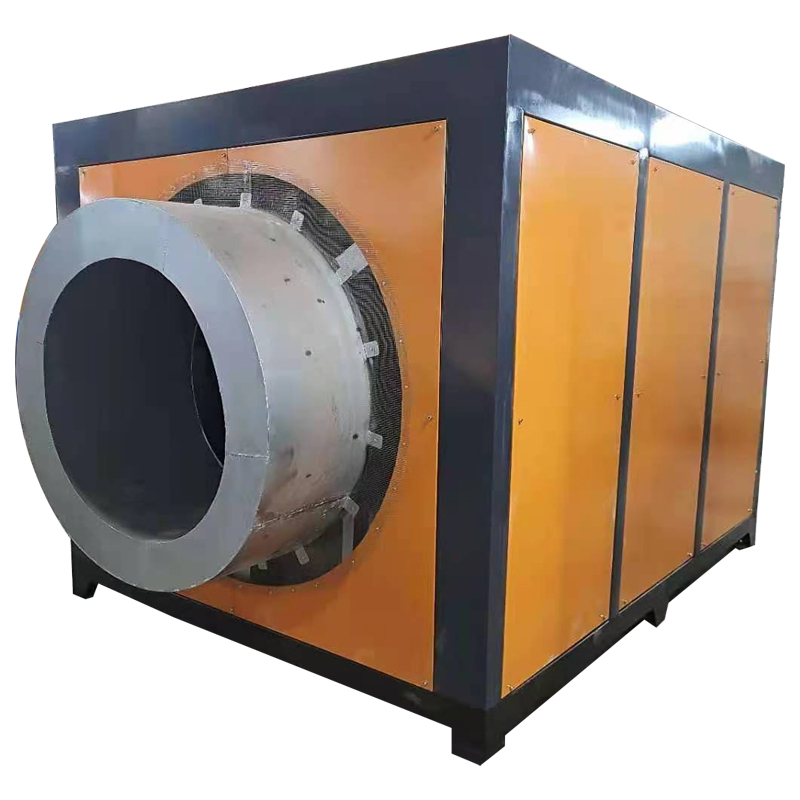

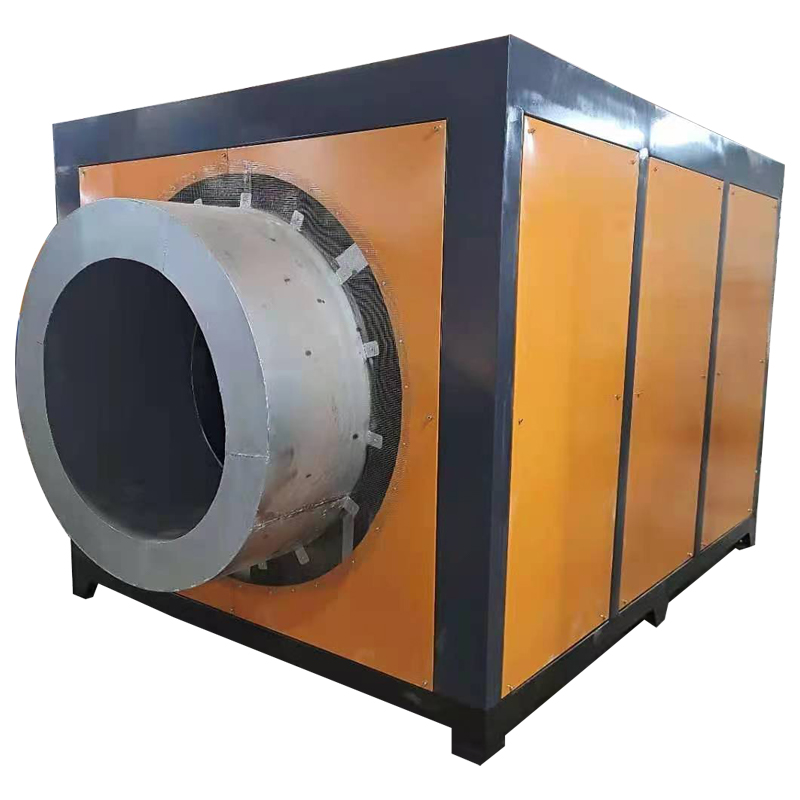

Drying hot air furnace

1. Direct heating of materials: direct combustion of fuel, high purification treatment to form flue gas of a certain temperature, that is, hot air, which is in direct contact with the material for heating, drying or baking.

2. High energy utilization rate: the use of advanced combustion technology and heat exchange system can make full use of the thermal energy of the fuel, make energy more effectively utilized, and reduce energy consumption and production costs.

3. Uniform temperature: hot air circulates in the drying chamber, which can make the material heated more evenly and avoid local overheating or uneven drying.

4. Fast drying speed: high-temperature hot air can quickly take away the moisture in the material, speed up the drying speed, and improve production efficiency.

5. Accurate temperature control: equipped with advanced temperature control system, it can accurately control the temperature of hot air and set appropriate temperature parameters according to the drying requirements of different materials.

6. Strong scale adaptability: there are drying hot air furnaces of different specifications and powers to choose from, which can meet both small-scale drying needs and large-scale industrial production drying tasks.

Drying hot air furnace uses fuel to burn directly, and then forms hot air after high purification, and then directly contacts the material for heating, drying or baking. It has become a replacement product for electric heat source and traditional steam power heat source in many industries. Use fuel to burn directly, and then forms hot air after high purification, and then directly contacts the material for heating, drying or baking. This method reduces fuel consumption by about half compared with steam or other indirect heaters.

The hot air furnace has been proved by compound fertilizer manufacturers in production tests: the heating area is large, the hot air volume is sufficient, and the temperature difference between the head and the tail is greatly reduced, so that the moisture content of compound fertilizer can be easily controlled within the specified range. The test proves that the use of hot air furnace controls the moisture content of the product, solves the big problem of fertilizer agglomeration, and at the same time reduces the amount of anti-caking agent, which reduces the production cost.

The fuel is solid fuel, such as coal and coke. The high-temperature combustion gas obtained after the combustion reaction of the fuel further contacts with the outside air, and after mixing to a certain temperature, it directly enters the drying room or baking room, contacts with the dried material, heats it, evaporates the water, and thus obtains the dry product.

Wide range of applications: It can be used to dry various types and forms of materials, such as grain, fruits and vegetables, wood, medicinal materials, seafood, mineral powder, etc. It is widely used in agriculture, food processing, medicine, chemical industry, building materials and many other industries.

The manufacturer provides 24*7 hours online support service. If users encounter problems during use, they can consult at any time through telephone, email, online customer service, etc., and the technicians will give answers and guidance in a timely manner.

Manufacturers will also provide users with equipment operation and maintenance training to help users better understand and use the equipment, extend the service life of the equipment, and improve production efficiency.