The daily output of 711*1500 steam corn machine is 200T

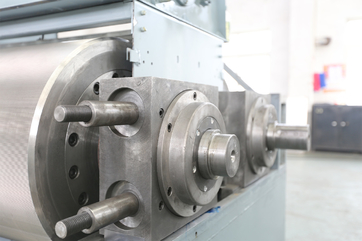

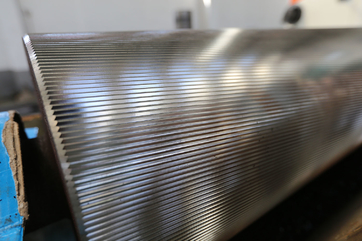

1, the roll of the sheet press is divided into fixed roll and dynamic roll, the roll adopts centrifugal casting cold loading process, and has a hard nickel-chromium molybdenum alloy working face. The oil is rotated by the pair of rolls to obtain a uniform grease sheet, and the thickness of the sheet is controlled by the set roll pressure and roll feed speed. There is a pressure cylinder between the moving and fixed rolls, and the uniform rolling pressure between the two rolls is changed by adjusting the pressure of the pump station. The roll is mounted horizontally on the base of the finishing mill through the tile base.

2. The roller rotates in SKF self-aligning double row cylindrical roller bearings fixed at both ends, and the bearings are wrapped in a strictly sealed bearing oil chamber. The centralized lubrication system on the left and right sides of the embryo rolling machine can ensure the lubrication effect of the bearings.

3. The bearing pressure cylinder is respectively installed on the tile seat on both sides of the roll. Provides the pressure adjustment necessary to keep the roll gap to the desired standard.

4, the base of the rolling machine has two kinds of casting and welding, which are treated by eliminating internal stress and finishing. The roller tile base is mounted on it.

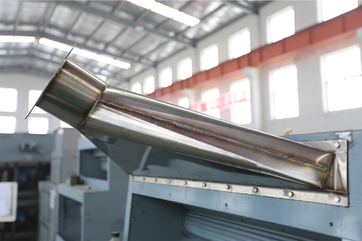

5, the feeding device, the stop door is used to control the flow of oil raw materials into the two rolls.

6, magnetic separation device, prevent metal debris into the roll, damage the roll, so often clean.

711*1500 steam corn machine daily output 200T motor power 90kw

Basic parameters:

Equipment brand: Bremetz

Device model: CF200TH711

Motor power: 45KW×2 sets

Roll size: 711*1500

Production: 200T/D, (10 tons per hour)

Processing materials: corn, (slightly lower soybean yield)

Weight: 11.8T

Equipment dimensions: Length 2700mm x width 2500mm x height 2000mm

Random accessories: host ×1; Motor ×2; Motor slide ×2; Drive belt ×2; Stainless steel feeding hopper ×1; Instructions ×1;