Corn flake making machine

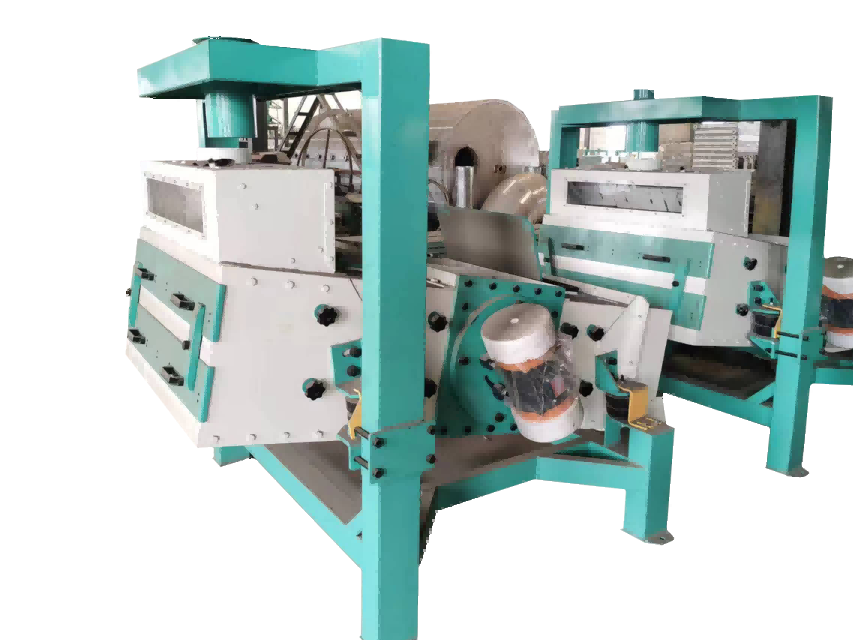

1. The equipment has a compact design, high degree of automation, and can be produced continuously. It can produce a large number of corn flakes per hour to meet the needs of large-scale production.

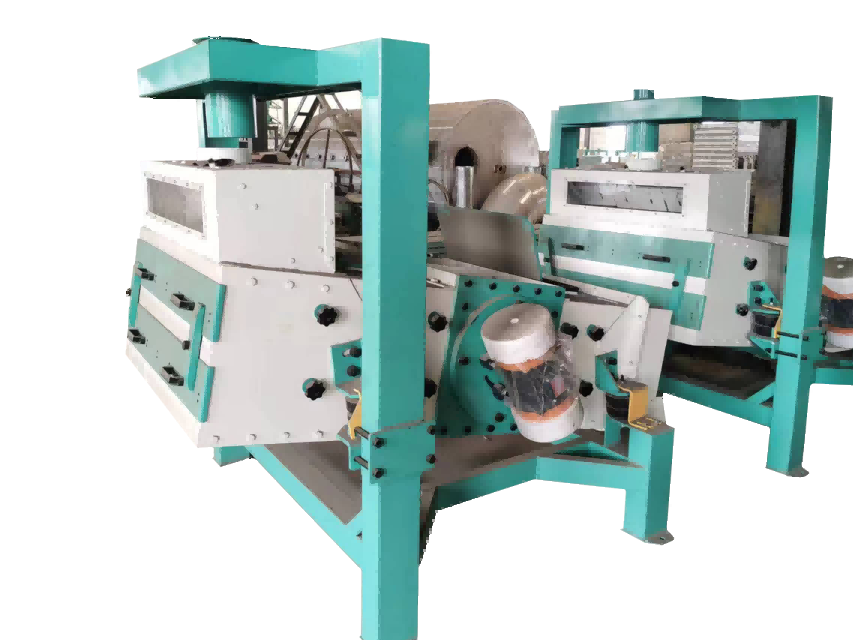

2. Equipped with precise temperature, humidity and pressure control systems, it can ensure the consistent quality of each batch of corn flakes.

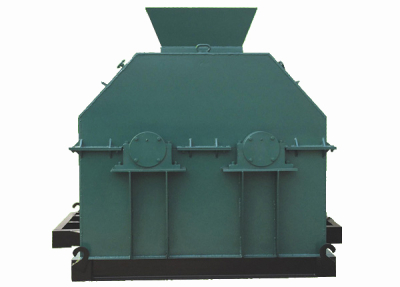

3. Not only can it use corn as the main raw material, but it can also be compatible with other grains, and can produce cereal flakes with different flavors and nutritional ingredients.

4. High-quality and durable materials are selected, and key components are specially treated with strong wear resistance and corrosion resistance, and have a long service life.

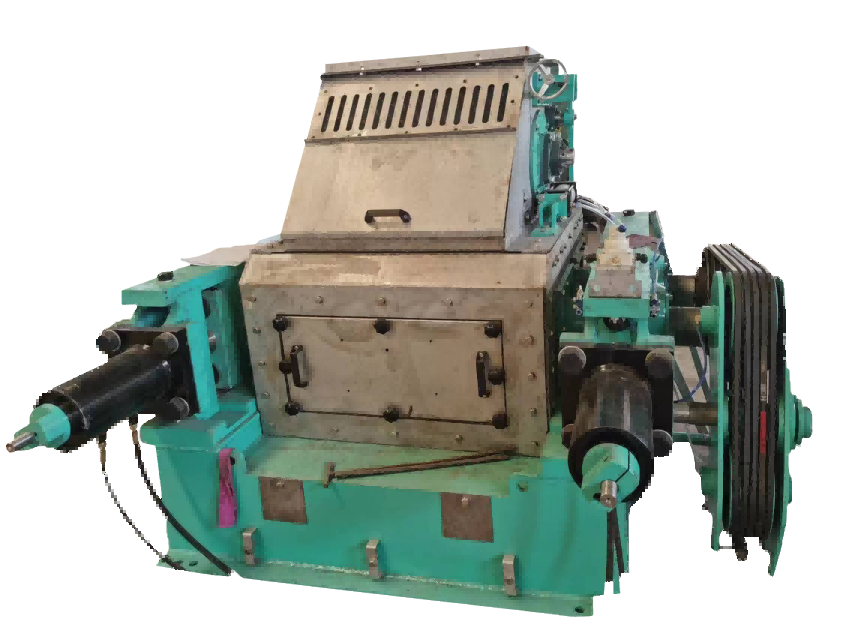

5. It integrates multiple functions such as raw material pretreatment, steaming, tableting, baking, etc., reducing production links and equipment investment.

Corn flour, flour, oat flour, buckwheat flour and other grains can be used as raw materials. Vitamins, minerals, cocoa, sugar and other nutritional enhancers and seasonings can be added as needed to produce corn flakes with different nutritional components and flavors.

The entire production process, from raw material mixing, extrusion, drying, tableting to spraying, can be automated to reduce manual intervention.

The use of advanced extrusion, flaking, baking and other process technologies can preserve the nutrients and natural flavors of the grains intact, making the corn flakes rich in nutritional value and good taste.