Organic fertilizer bucket elevator, adaptable to various needs

Today, as the concepts of environmental protection and sustainable development are deeply rooted in people's hearts, the organic fertilizer industry is booming, and the importance of efficient material conveying equipment for organic fertilizer production is self-evident. Our company has been committed to providing high-quality equipment solutions for the organic fertilizer industry. Recently, our organic fertilizer bucket elevator has achieved a series of remarkable results in technological innovation and market application.

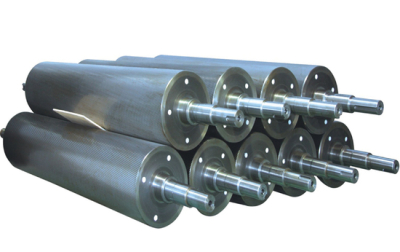

Through the unremitting efforts of the R&D team, we have deeply optimized the technology of the organic fertilizer bucket elevator. In terms of structural design, the material and shape of the hopper have been improved, and a new composite material that is more corrosion-resistant and durable has been selected, so that the hopper can maintain good performance when facing organic fertilizers with different pH and humidity. At the same time, the shape of the hopper has been simulated and analyzed by fluid mechanics. Whether it is dealing with powdered, granular or block organic fertilizers, it can achieve more efficient scooping and unloading, greatly reducing the problems of material residue and blockage.

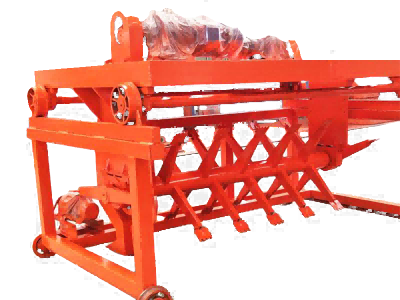

The transmission device has also ushered in a major upgrade. The new chain and belt transmission system not only enhances the carrying capacity, but also improves the transmission efficiency. The belt adopts advanced anti-slip and wear-resistant technology to ensure stable operation during the transportation process, further extending the service life of the equipment. In addition, the intelligent upgrade of the drive motor and control system is a highlight. By introducing an advanced PLC control system, the elevator can achieve precise speed control and overload protection. Operators can easily adjust the lifting speed according to the flow rate and production needs of organic fertilizers, and the system will monitor the operating status of the equipment in real time. Once an overload or abnormal situation occurs, it can quickly and automatically shut down, effectively avoiding equipment damage and ensuring the continuity of production.