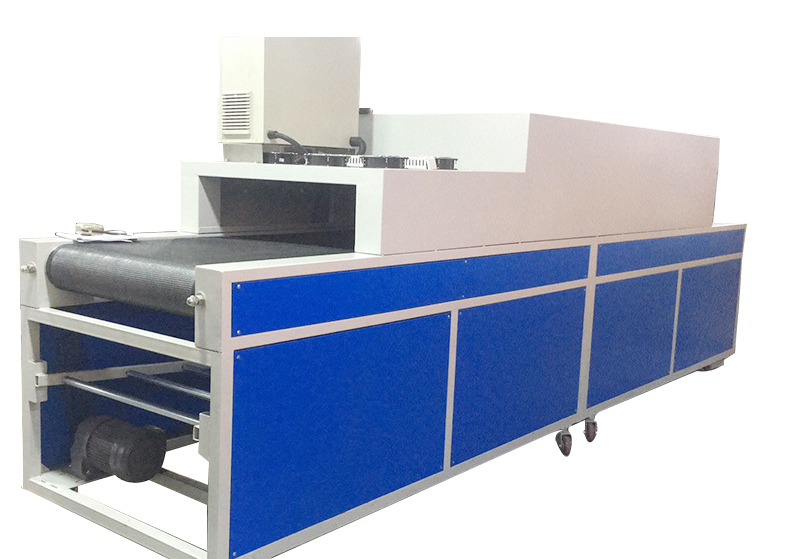

Fully automatic tunnel drying line creates excellent quality

Recently, the fully automatic tunnel drying line project developed and produced by our company has made a series of major breakthroughs, which has injected strong momentum into the company's development in the industry and is expected to bring transformative impacts to related industries.

In terms of technological innovation, the fully automatic tunnel drying line adopts a new intelligent temperature control system, which can achieve precise control of the temperature in the drying room through high-precision temperature sensors and advanced algorithms. The new drying line optimizes the hot air circulation design, and through the special air duct layout and efficient fan selection, the circulation of hot air in the tunnel is more efficient and uniform.

In the production and manufacturing process, in order to meet the growing market demand, the company has increased the investment in production facilities and expanded production capacity. A modern production workshop has been newly built, and a batch of advanced automated production equipment and precision testing instruments have been introduced to further improve production efficiency and product quality stability.

The company's senior management said that the success of this fully automatic tunnel drying line project is the result of the joint efforts of all employees of the company, and it is also a reflection of the company's adherence to the innovation-driven, quality-first development strategy. In the future, the company will continue to increase investment in technology research and development, market expansion and production and manufacturing, continuously improve product performance, enrich product lines, and provide high-quality drying solutions for customers in more industries.