Conveyor line bag sewing machine meets diverse needs

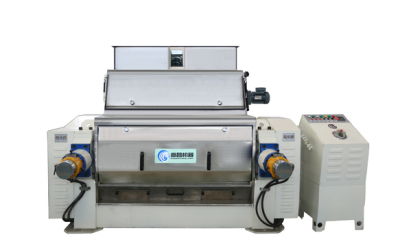

Through unremitting efforts, the company's R&D team has successfully overcome a series of technical problems and significantly improved the performance and stability of the conveyor line bag sewing machine. The new generation of conveyor line bag sewing machine adopts an advanced automatic control system, which can accurately control the sewing speed, stitch length and thread tension to ensure that every seam is even and firm, greatly reducing the defective rate and meeting the needs of Customers have strict requirements for high-quality packaging.

At the same time, we have introduced innovative sensor technology to equip the equipment with intelligent detection functions. It can monitor the position, thickness of the bag and various parameters during the sewing process in real time. Once an abnormality is discovered, it will automatically adjust or issue an alarm immediately, effectively avoiding production interruptions due to material differences or machine failures, and greatly improving production efficiency and Continuity.

The company always adheres to market demand as the guide and constantly optimizes product design, so that conveyor line bag sewing machines can be widely used in many industries. Whether it is the packaging of granular or powdery materials such as grain, feed, chemical raw materials, or the sewing of packaging bags for large items such as industrial parts and textiles, our equipment can demonstrate excellent adaptability and reliability, serving different needs. Customers in the industry provide efficient and precise packaging solutions.