Fully automatic bucket elevator

1. Small footprint: The Fully automatic bucket elevator has a small cross-sectional dimension and can be installed and used in a limited space, saving space in the production site and making the layout of the conveying system more compact.

2. Large lifting height: It can achieve higher vertical conveying, can lift materials from low to high, and meet the conveying needs of different height differences.

3. Large conveying capacity: The design of the hopper enables it to convey a large amount of material per unit time. By reasonably selecting the size, shape and number of the hopper, and matching the appropriate drive device and conveying speed, efficient material conveying can be achieved to meet the needs of large-scale production.

4. Small driving power: The use of inflow feeding, induction unloading and large-capacity hopper intensive layout, there is almost no return and digging when the material is lifted.

5. Stable running speed: The running speed of the bucket elevator can be adjusted according to actual needs, and the speed is relatively stable during operation, which can ensure the continuous conveying of materials and improve production efficiency.

6. Strong adaptability to material types: It can not only lift general powdery and small granular materials, but also lift materials with high abrasiveness, and has relatively few requirements on the type and characteristics of materials.

Fully automatic bucket elevator is a continuous conveying equipment used to convey powder, granular and small block materials vertically or obliquely. It lifts materials from low to high through a series of buckets evenly distributed on traction components (such as belts or chains). It is widely used in many industries such as food, mining, chemical industry, building materials, etc. It is a key equipment to achieve efficient vertical conveying of materials.

Bucket elevators can achieve efficient vertical transportation with a wide range of lifting heights, ranging from a few meters to tens of meters. This enables it to effectively transport materials from one floor to another in multi-story factories, storage facilities and other scenarios, solving the problem of material transportation in vertical space.

product name:Belt conveyors

product 【specification 】:Non-standard can be customized

【Manufacturer】:bremetz

product material :Stainless steel (201/304/314/316), nylon material, etc.

product 【performance】:Large conveying force, flexible transmission, good air permeability and stable transportation

Application range:Food processing, textile, electric power, express delivery, construction and other transportation

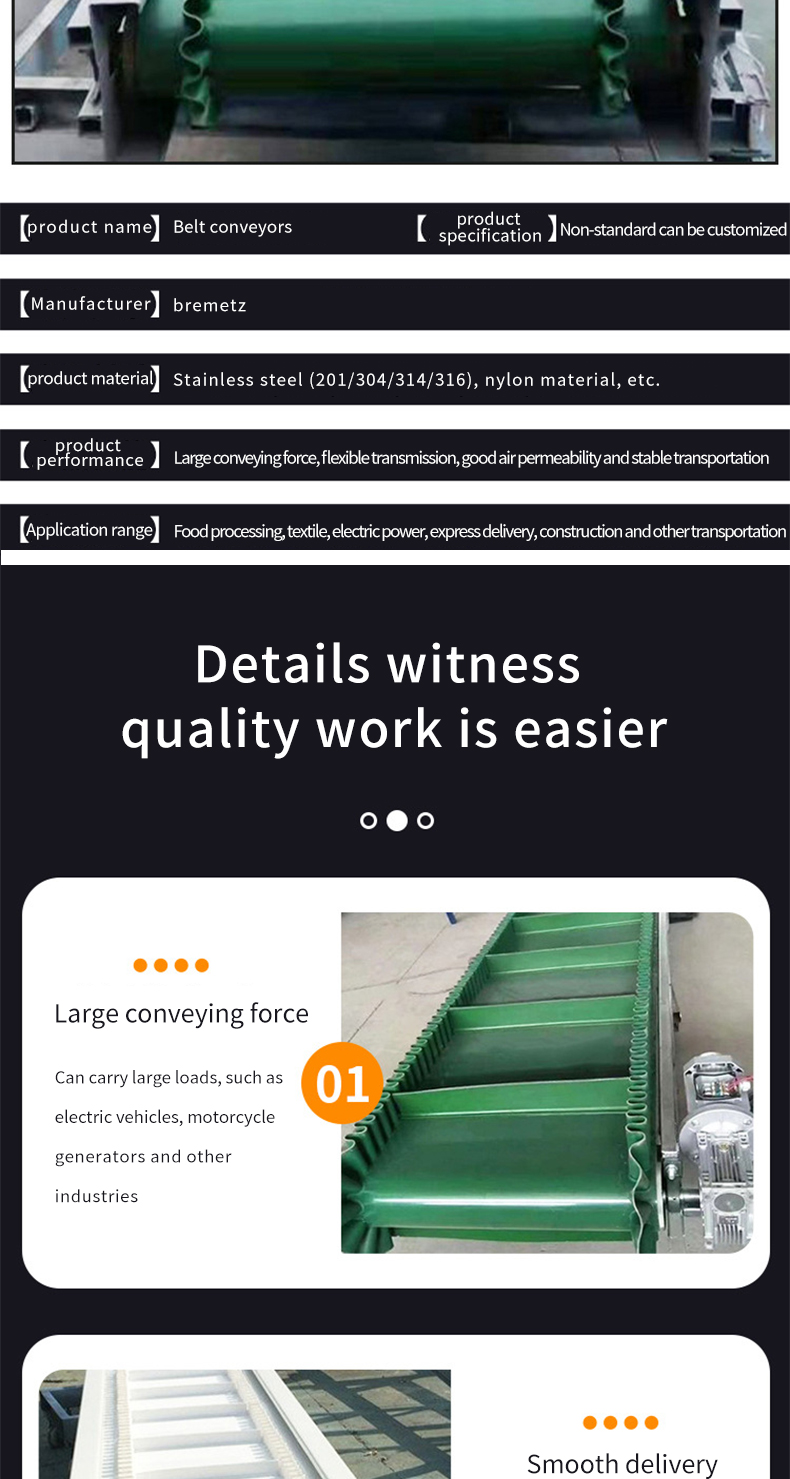

Large conveying force,Can carry large loads, such as electric vehicles, motorcycle generators and other industries.

Smooth delivery,Accurate and stable conveying speed can ensure accurate synchronous conveying.

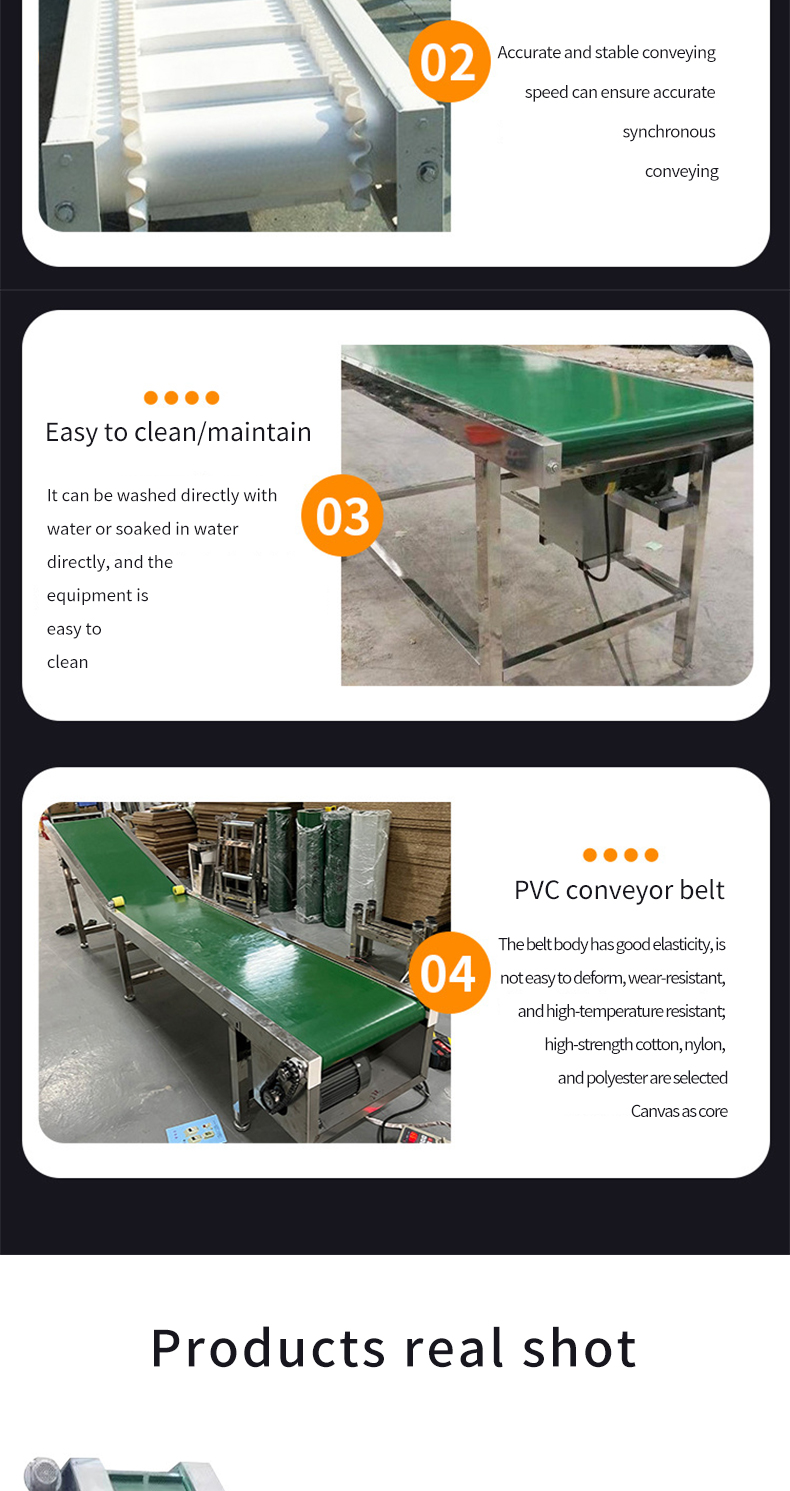

Easy to clean/maintain,It can be washed directly with water or soaked in water directly, and the equipment is easy to clean.

PVC conveyor belt,The belt body has good elasticity, is not easy to deform, wear-resistant, and high-temperature resistant; high-strength cotton, nylon, and polyester are selected Canvas as core.

During operation, bucket elevators have less vibration and noise. This is due to its evenly distributed buckets and stable traction component operation mode, which reduces problems such as component wear and material spillage caused by equipment vibration, provides a relatively comfortable working environment for operators, and also extends the service life of the equipment.

The company provides a professional installation team to install the bucket elevator to the location specified by the user. During the installation process, strictly follow the equipment's installation instructions and relevant standards to ensure that all parts of the equipment are installed correctly and firmly, such as the vertical installation of the barrel, the correct tensioning of the traction components, and the uniform distribution of the bucket.