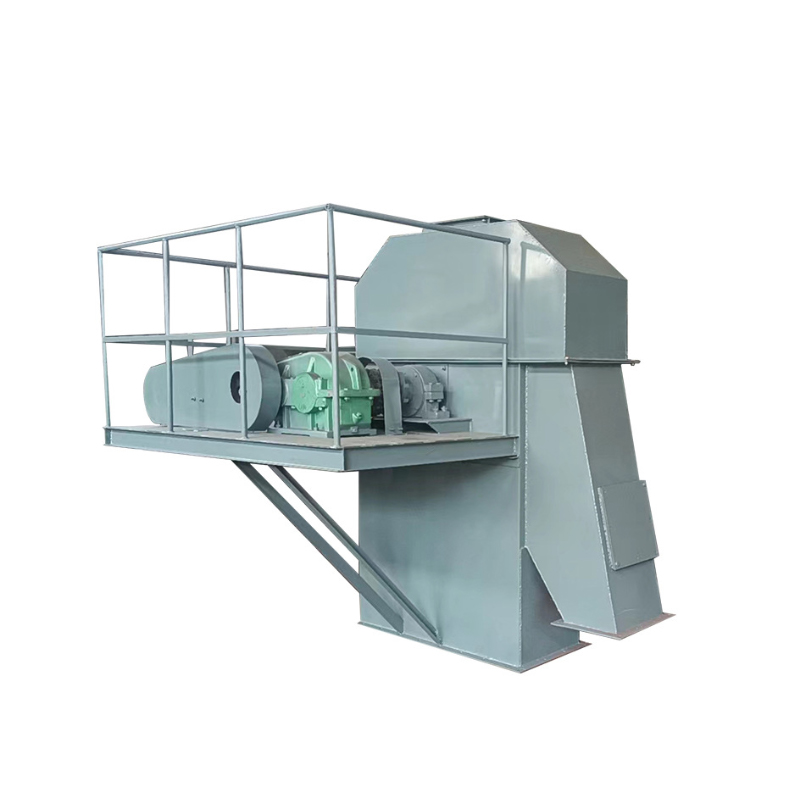

Fertilizer High Efficiency Bucket Elevator

1. It can meet the transportation needs of a large number of materials in the fertilizer production process. The conveying capacity of different types of elevators can reach 5.4-100 tons/hour, which can effectively improve production efficiency and is suitable for large-scale fertilizer production enterprises.

2. The lifting speed is generally between 1.4-2m/s, which can quickly lift the fertilizer from a low place to a high place, reducing the residence time of the material during the transportation process, and further improving the overall production efficiency.

3. It can transport fertilizer materials in different forms such as granular and powdery, and can also handle materials such as blocky, heavy, and abrasive materials.

4. It has good adaptability to fertilizer particles or powders of different particle sizes, and the particle size of the materials it can handle is generally between 25-70mm.

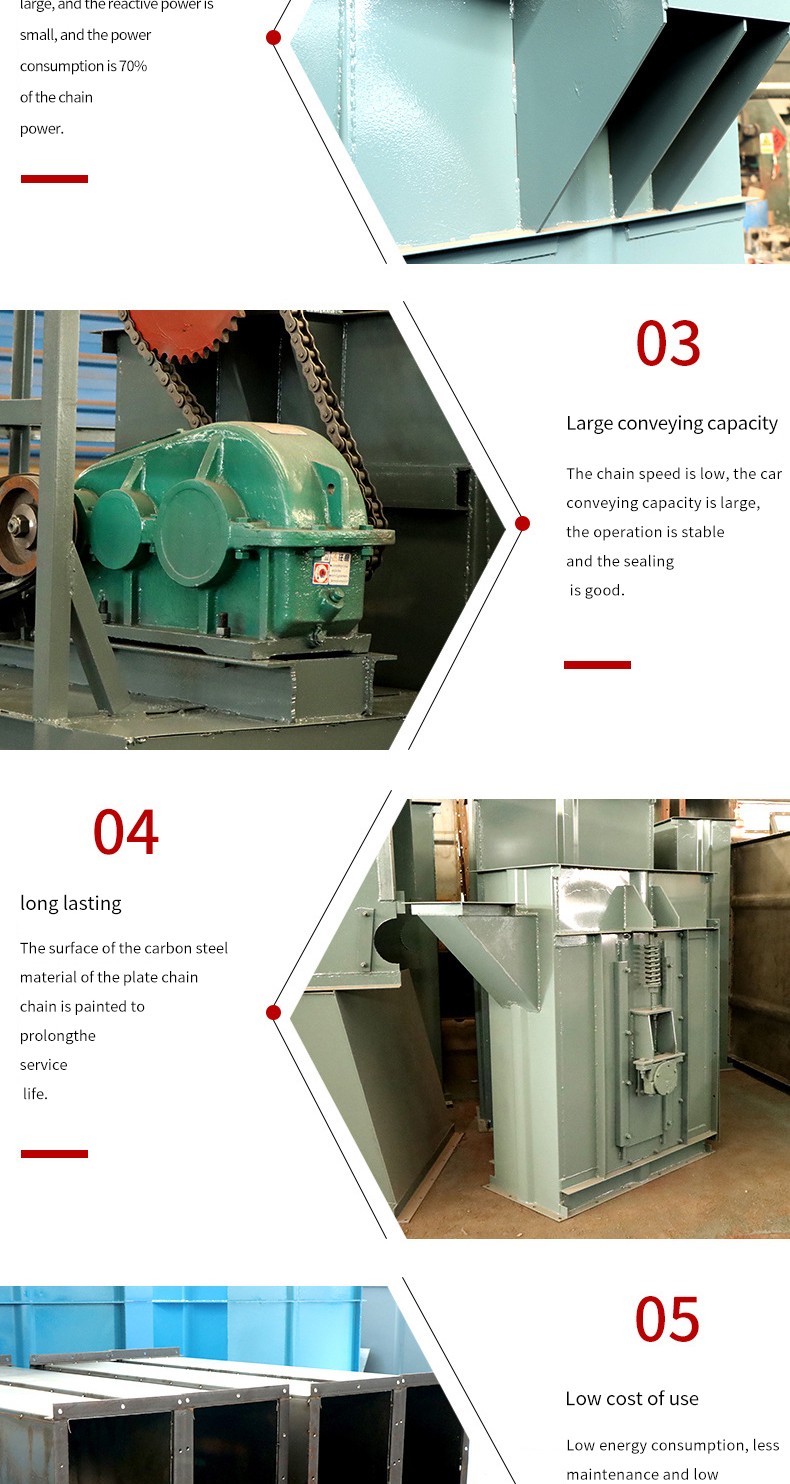

5. It adopts inflow feeding and gravity-induced unloading. This design makes the material almost free of return and digging during the lifting process, and has less invalid power.

6. The feeding adopts inflow, and there is little extrusion and collision between materials, which reduces mechanical wear.

The fertilizer high-efficiency bucket elevator is a key equipment specially designed for vertical material transportation in fertilizer production and storage. It can efficiently and stably lift various forms of fertilizers, including granules, powders, blocks, etc., from a lower position to a higher position, and plays an extremely important role in the entire fertilizer industry chain.

It has a large conveying capacity, which can vary from several tons to tens of tons or even hundreds of tons per hour according to different models, and can meet the production needs of small fertilizer plants to large chemical companies. At the same time, the lifting speed is moderate, generally around 1 to 2 meters per second.

It is capable of handling various forms of fertilizer materials, whether it is powdered fertilizer with fine particles, granular fertilizer with different particle sizes, or even block-shaped fertilizer products with high specific gravity and high abrasiveness, and can achieve efficient transportation.

The inflow feeding and gravity-induced unloading methods are adopted. There is almost no material return and digging during the lifting process, and the reactive power is small. Compared with the traditional chain hoist, the energy consumption can be greatly reduced, and the saving ratio can reach about 25% to 35%.

Due to the reasonable feeding method, there is little squeezing and collision between materials, which reduces mechanical wear. In particular, the use of key components such as high-strength wear-resistant chains greatly extends the service life of the equipment.

With stable operating performance and high-strength traction components, it can achieve a higher lifting height, generally up to 40 meters to 50 meters or even higher, which can meet the material transportation requirements of multi-story factories or production layouts at different heights.

The casing is made of high-quality steel and is fully welded. It has multiple reinforcing ribs inside, and has strong overall rigidity and sealing, which effectively prevents the leakage of fertilizer dust during transportation. This not only reduces material waste, but also protects the production environment and the health of operators, meeting the requirements of environmental protection and safe production.