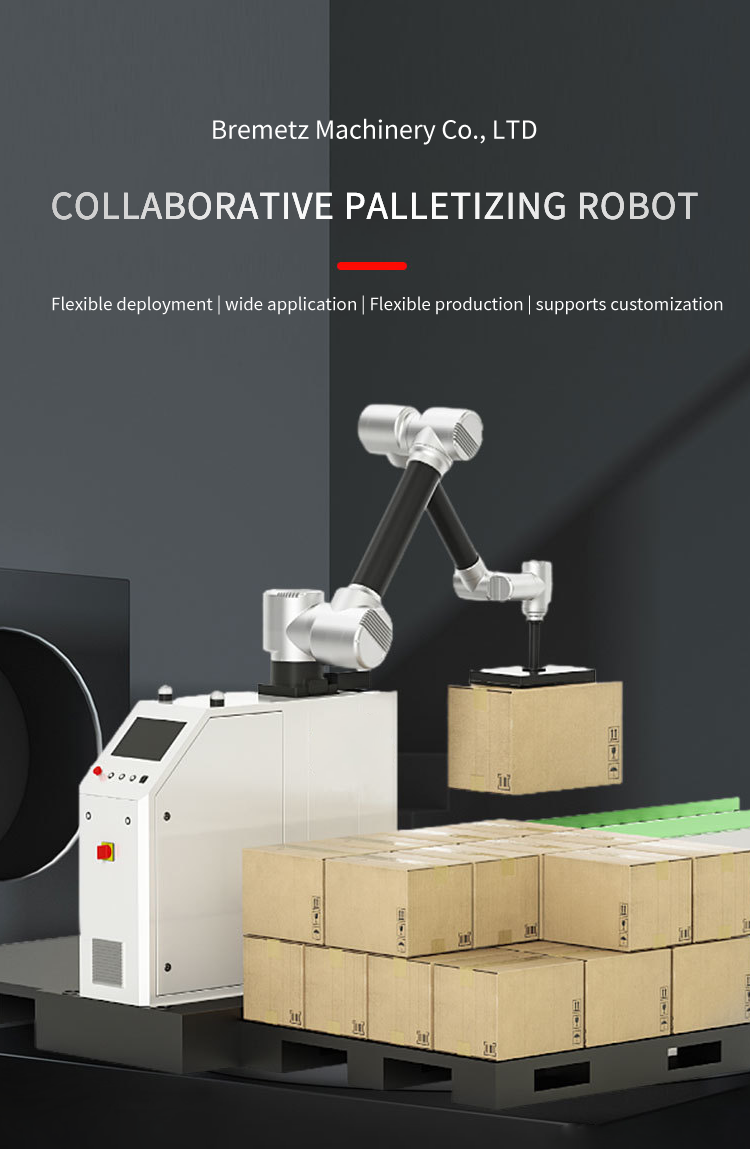

Collaborative palletizing robot

1. It can work uninterruptedly for a long time without being restricted by factors such as fatigue and time, which can greatly improve the palletizing speed and work efficiency.

2. Equipped with advanced sensors and control systems, it can accurately grab and place items to ensure that the position of items on the pallet is accurate.

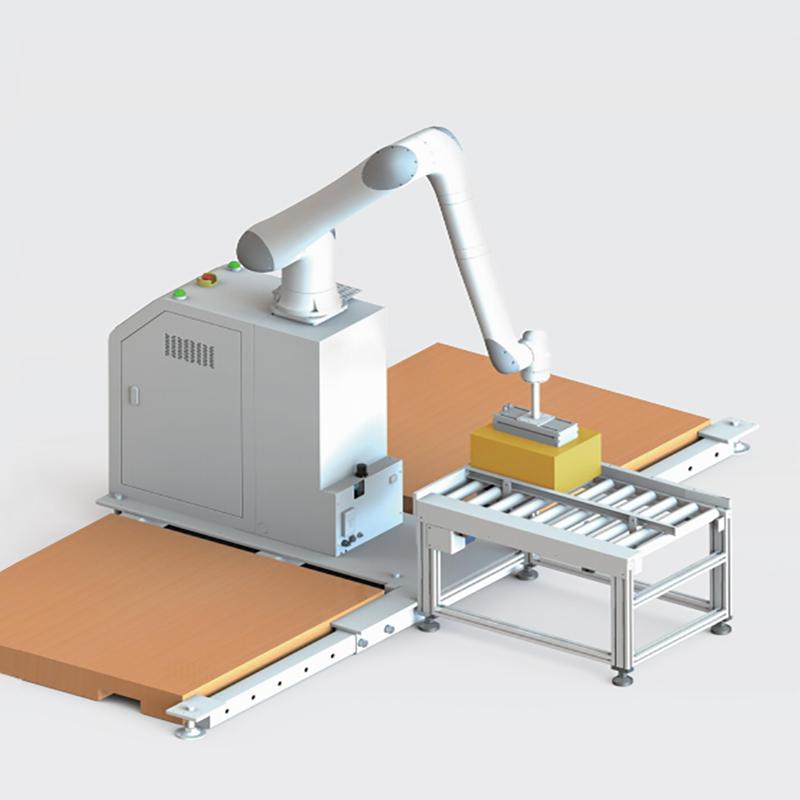

3. It is suitable for palletizing items of various shapes, sizes and weights. By replacing different end effectors or adjusting programs, it can easily cope with different product packaging forms.

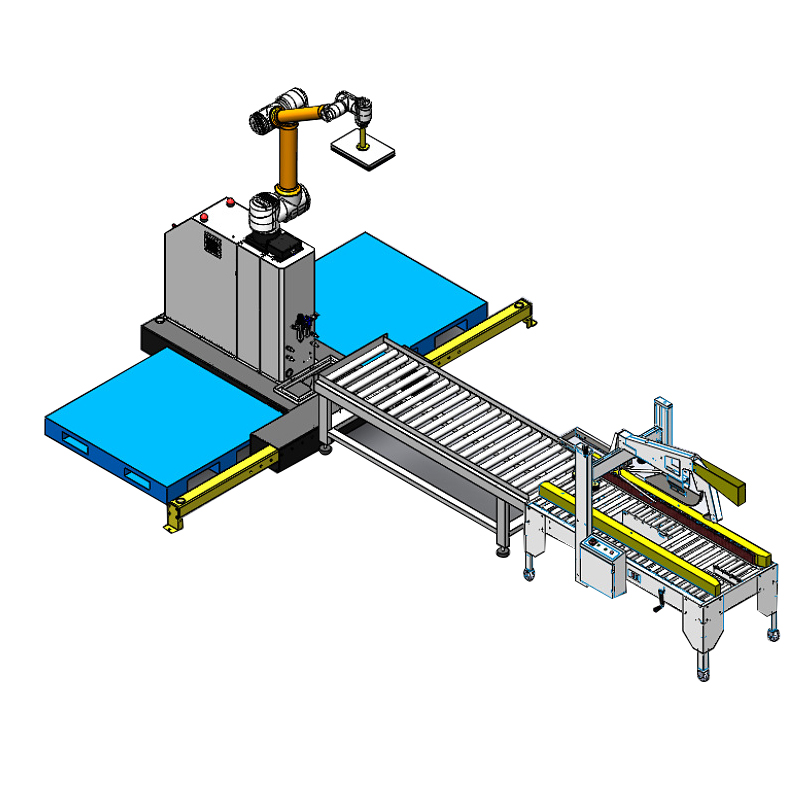

5. The position, mode and process of palletizing can be flexibly adjusted according to the actual situation of the production line and changes in production needs.

This collaborative palletizing robot is an advanced automation equipment designed for modern industrial production and logistics warehousing. It integrates precision machinery manufacturing, intelligent sensing technology, advanced control algorithms and efficient power drive systems to achieve efficient, accurate, safe and flexible palletizing operations.

The control system has fast data processing capabilities and precise motion control algorithms, and can respond promptly to information fed back by sensors, ensuring that the robot can maintain high-precision operations at high speeds and meet the company's needs for large-scale production.

Able to operate strictly according to the preset pallet type and spacing requirements to ensure that the goods are arranged neatly and firmly on the pallet, effectively avoiding the collapse and displacement of goods during transportation and storage.

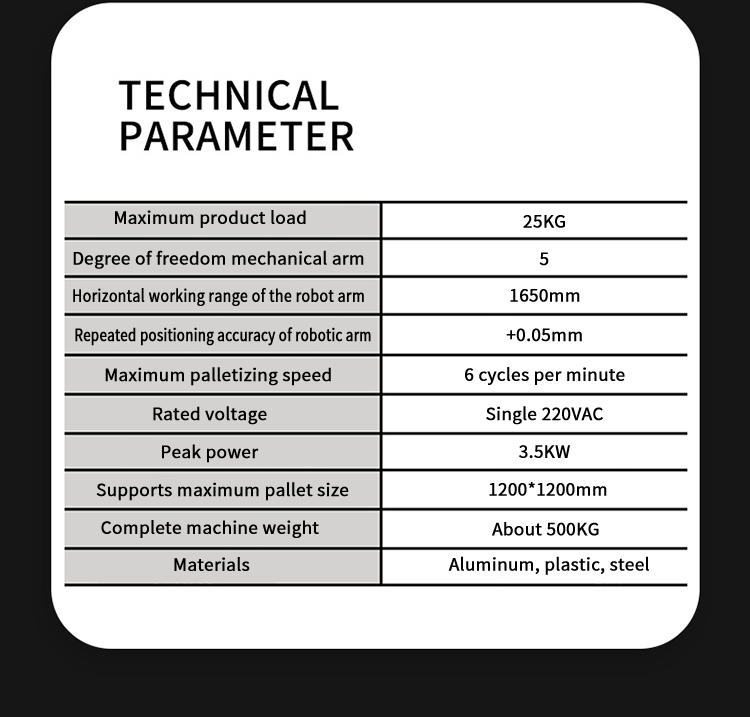

Maximum product load:25KG

Degree of freedom mechanical arm:5

Horizontal working range of the robot arm:1650mm

Repeated positioning accuracy of robotic arm:+0.05mm

Maximum palletizing speed:6 cycles per minute

Rated voltage:Single 220VAC

Peak power:3.5KW

Supports maximum pallet size:1200*1200mm

Complete machine weight:About 500KG

Materials:Aluminum, plastic, steel

By replacing different types of end effectors and adjusting the robot's control program, it can easily meet the palletizing needs of goods in various shapes, sizes, weights and packaging forms.

Using advanced force and visual sensor fusion technology, the collaborative palletizing robot can perceive the surrounding environment and the position and movement of operators in real time.