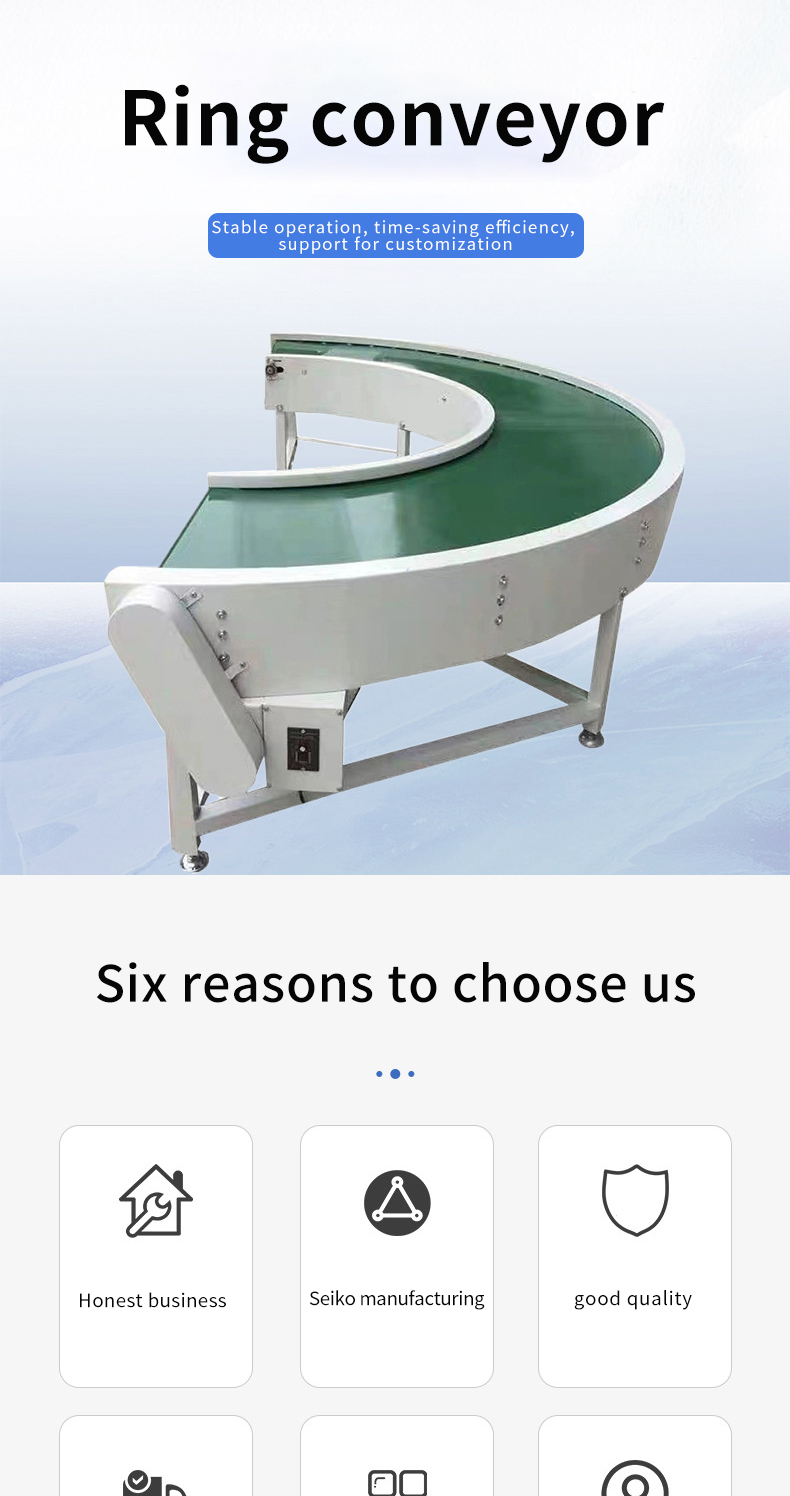

Belt corner machine

1. It can realize the smooth transition between the conveying lines in different directions of materials, and can be flexibly arranged in places with limited space such as production workshops and warehouses.

2. It adopts advanced transmission technology and high-quality conveyor belts, runs smoothly, and can ensure that the materials maintain a stable conveying state during the turning process.

3. According to the characteristics of different materials, the appropriate conveyor belt material, width, pattern and turning radius can be selected.

4. The structure is relatively simple, the main components are easy to disassemble and replace, and daily maintenance and maintenance work are relatively convenient.

5. During operation, the friction between the belt and the roller, roller and other components is small, and the noise generated is low.

The conveyor belt is driven by a driving device. When the material is transported to the turning part along the conveyor belt, the specially designed turning structure, such as the curved conveyor belt and guide roller, allows the material to turn smoothly under the drive of the conveyor belt, thereby changing the conveying direction of the material to adapt to different production processes and site layout requirements.

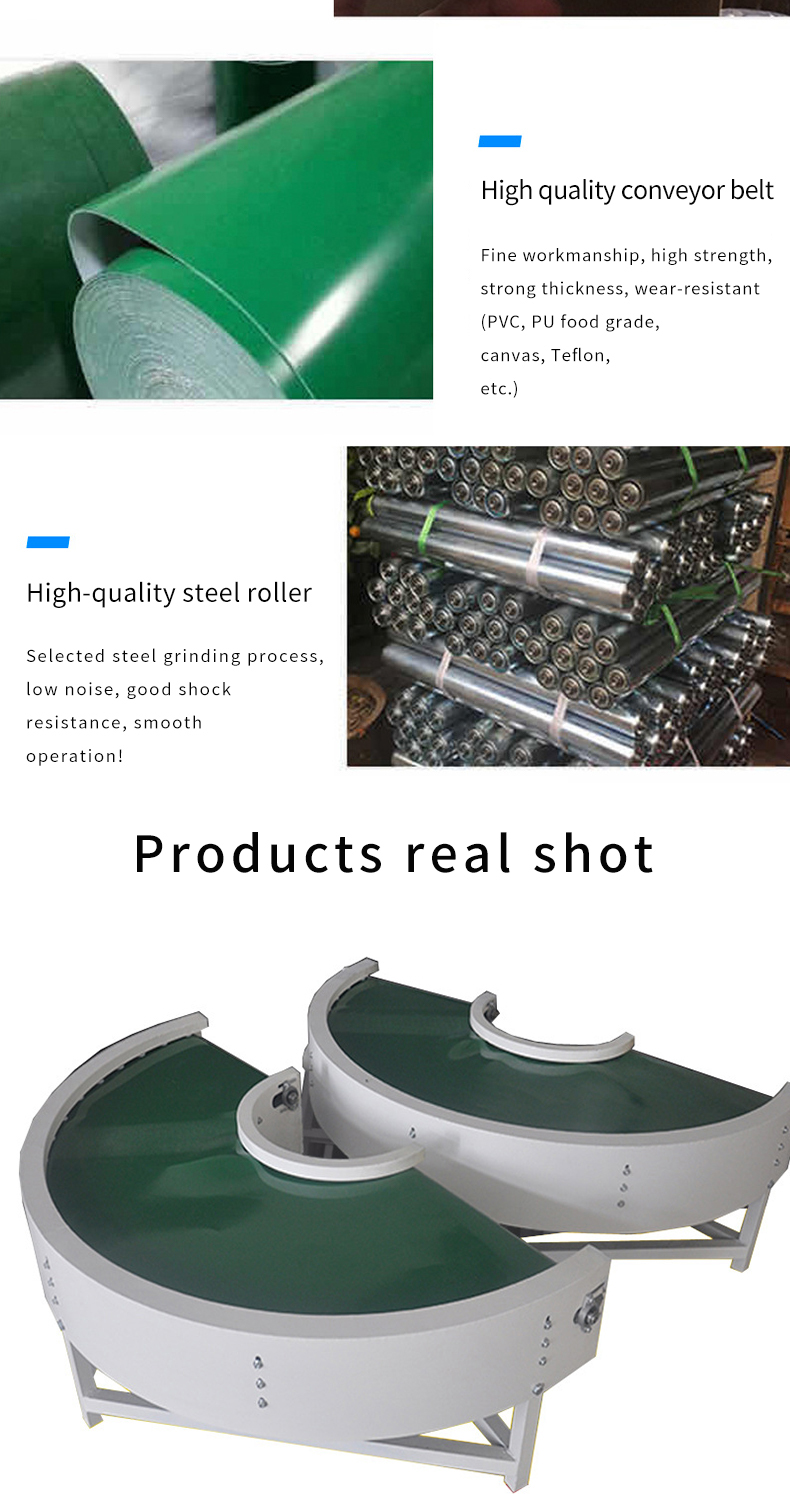

The conveyor belt is a core component, usually made of rubber, silicone, PVC, PU and other materials. It has the characteristics of wear resistance, oil resistance, corrosion resistance, etc., and is selected according to different use environments and the characteristics of the conveyed materials.

The driving device is generally composed of a motor, a reducer, etc., which provides power for the belt curve machine to ensure that the conveyor belt can run at the set speed and direction.

The driving device is generally composed of a motor, a reducer, etc., which provides power for the belt curve machine to ensure that the conveyor belt can run at the set speed and direction.

The roller group includes active rollers and driven rollers. The active rollers are connected to the driving device to drive the conveyor belt to move; the driven rollers play a supporting and guiding role to keep the conveyor belt stable.

The rack is usually made of carbon steel, stainless steel or aluminum profiles, etc. It provides support and fixation for the entire equipment to ensure the stability and reliability of the equipment during operation.