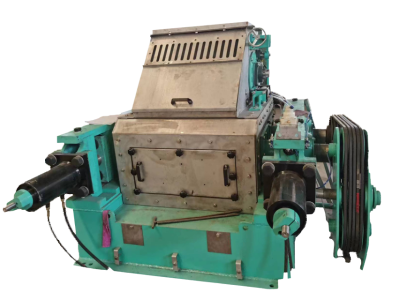

Organic fertilizer disc mixer

1. High mixing efficiency: The special disc structure and stirring arm design enable the material to be fully turned and stirred in the disc, and achieve a uniform mixing state in a short time.

2. High mixing uniformity: During the mixing process, the material can be fully stirred in both the radial and axial directions to ensure that all kinds of raw materials are evenly distributed.

3. Small footprint: The overall structure is compact and occupies less space. In a limited production site, it can be flexibly laid out to save space costs.

4. Top feeding and bottom discharging: This design method conforms to the law of material flow, facilitates the continuous operation of feeding and discharging, and realizes an automated production process.

5. Reducer drive: It adopts a cycloidal pinwheel reducer drive, which rotates smoothly and can effectively reduce the vibration and noise during the operation of the equipment.

6. Wear-resistant material application: Key components such as spiral blades are made of highly wear-resistant special alloys, which can effectively resist material wear and reduce equipment failure rate during long-term mixing.

Bremetz organic fertilizer disc mixer is a special mixer for fertilizer industry. It is a mixing equipment specially used for organic fertilizer mixer produced by our company. The equipment consists of a mixing disc, a discharge port, a mixing arm, a bracket, a gear box and a transmission mechanism. The design concept is advanced, the machine is compact and practical. It has the advantages of long service life, fast mixing speed, high mixing uniformity and thorough unloading.

Excellent mixing efficiency: The unique mixing mechanism ensures that the materials are deeply interwoven in the radial and axial directions, and the conventional mixing uniformity exceeds 90%, which meets the precise formulation requirements of organic fertilizers and improves fertilizer efficiency and quality stability.

Efficient production rhythm: Reasonable structure and power configuration facilitate rapid mixing, with a processing volume of several cubic meters to tens of cubic meters per hour, suitable for production of different scales, and shortening the production cycle.

Stable and reliable operation: high-quality material selection, precision transmission and sealing design, shock and noise reduction, leakage and dust prevention, long-term high-intensity operation, few failures and simple maintenance.

Wide range of material adaptation: suitable for both dry and wet materials, coarse and fine particles, flexible to cope with a variety of organic fertilizer raw materials, and even has excellent mixing effect on high-fiber and sticky materials.

Scope of application: It is widely used in fertilizer production fields such as organic fertilizer plants, compound fertilizer plants, and biological fertilizer plants. It also plays a role in some chemical and feed industries involving the mixing of powdered and granular materials. It is an "all-rounder" for uniform fusion of materials.

Installation and commissioning: A professional team will come to your site to accurately install the equipment according to site conditions and upstream and downstream connections, debug the equipment to the best operating state, calibrate the mixing speed and feeding and discharging parameters to ensure "ready to use".

Training guidance: Customized training for operators, covering equipment structure principles, daily operation procedures, and safety precautions; analyze mechanical maintenance, electrical maintenance points and troubleshooting methods for maintenance personnel to improve practical operation capabilities.