Fertilizer drying process introduction

Fertilizer drying is a key link in the fertilizer production process. Its purpose is to remove excess water from the fertilizer so that the fertilizer reaches an appropriate moisture content for easy storage, transportation and use. The appropriate drying process can not only ensure the quality of the fertilizer, but also improve production efficiency and reduce energy consumption.

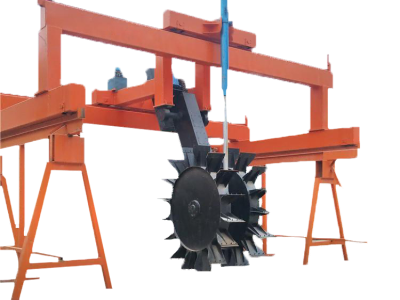

Drum drying process:

Drum drying is one of the most common fertilizer drying processes. The fertilizer raw materials are fed into the rotating drying drum through the feeding device. The drum is installed at a certain angle and rotates slowly under the drive of the motor. There is a lifting plate inside the drum. As the drum rotates, the lifting plate continuously lifts and drops the fertilizer, so that the fertilizer forms a "curtain" in the drum and is fully in contact with the hot air. The hot air is generated by the heat source device and enters the drum through the pipeline to exchange heat with the fertilizer. The moisture in the fertilizer evaporates under the action of the hot air and turns into water vapor, which is then discharged out of the drum by the induced draft fan.

Drum speed: generally controlled at 2-8 revolutions per minute. If the speed is too fast, the fertilizer stays in the drum for too short a time, and the moisture does not have time to fully evaporate, affecting the drying effect; if the speed is too slow, the production efficiency is low.

Drying temperature: varies according to the type of fertilizer and the initial moisture content.

Hot air flow rate: The flow rate of hot air determines the efficiency of heat transfer and the speed of water evaporation. If the flow rate is too fast, the fertilizer particles that are not fully dried may be blown out of the drum; if the flow rate is too slow, the drying time will be prolonged. Usually, the flow rate of hot air is controlled at 3-8m/s.