Fully automatic vacuum sealer

1. It can run continuously for a long time without frequent shutdown, and can maintain stable packaging quality and production efficiency

2. It can effectively extract the air in the packaging bag, reduce the oxygen content, and inhibit the growth and reproduction of microorganisms.

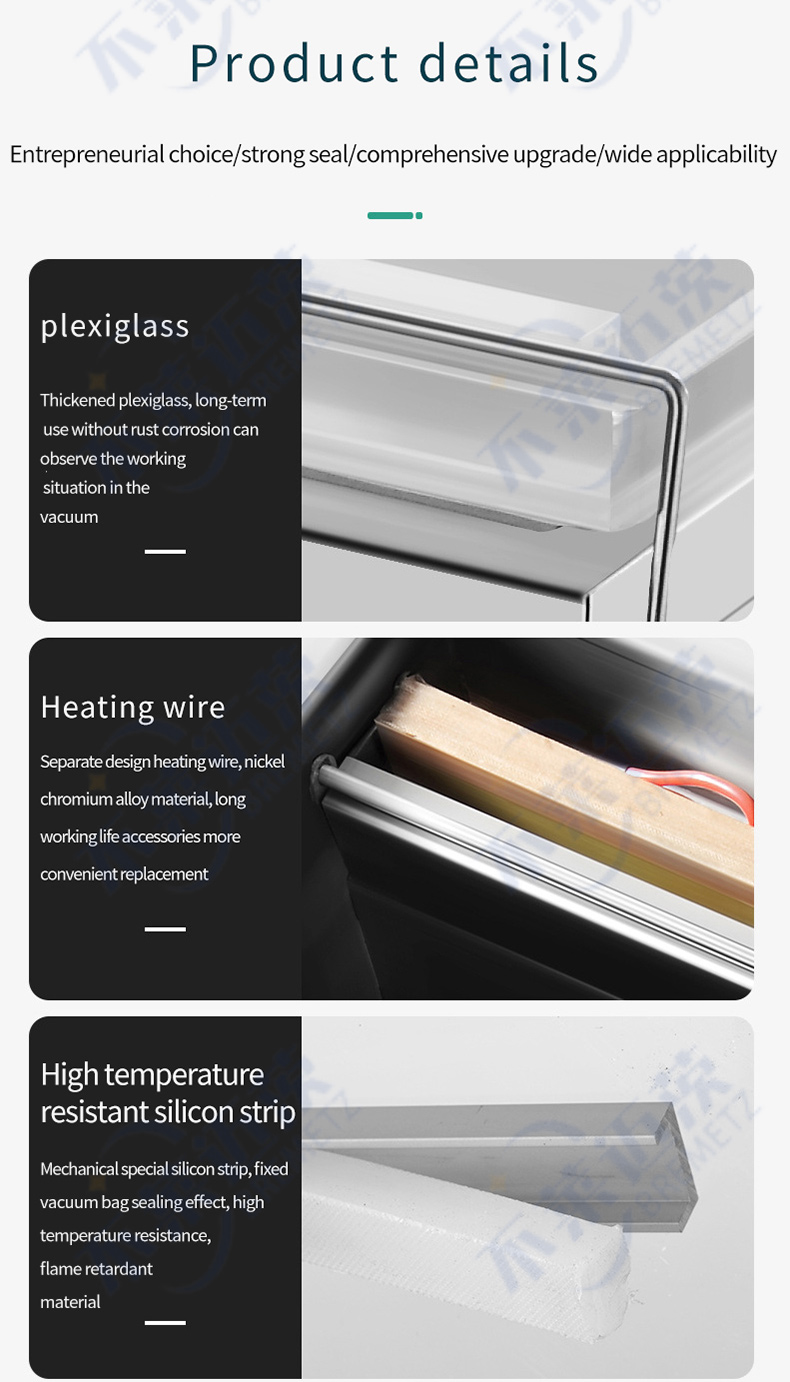

3. It adopts advanced sealing technology and high-quality sealing materials to form a uniform and strong seal.

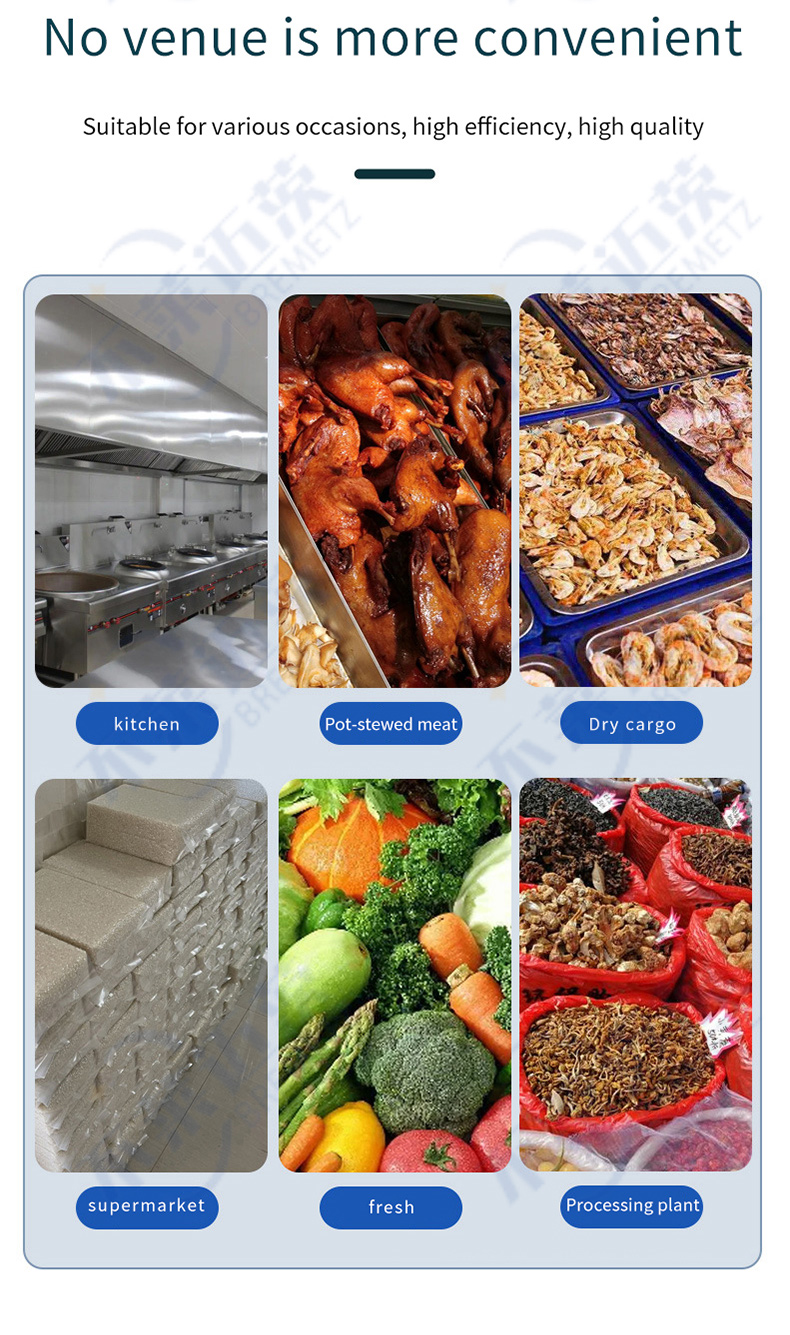

4. It can package various forms of products such as solids, liquids, soft objects, fragile items, etc., and can also carry out various packaging forms such as vacuum soft film packaging and hard film inflation packaging.

5. It is suitable for packaging bags of different materials, such as plastic bags, aluminum foil bags, etc., which can meet the packaging needs of different users and different products.

This fully automatic vacuum packaging machine is a high-performance packaging equipment that integrates advanced technology and exquisite craftsmanship. It is designed to provide efficient, accurate and reliable vacuum packaging solutions for various companies. It is suitable for many industries such as food, electronics, hardware, chemicals, etc.

The vacuum pump has a strong suction capacity and can quickly extract the air in the package in a short time to achieve the preset vacuum requirements, ensuring that the oxygen content in the package is reduced to the minimum.

The sealing device can accurately control key parameters such as sealing temperature, time and pressure to ensure the firmness and sealing of the seal.

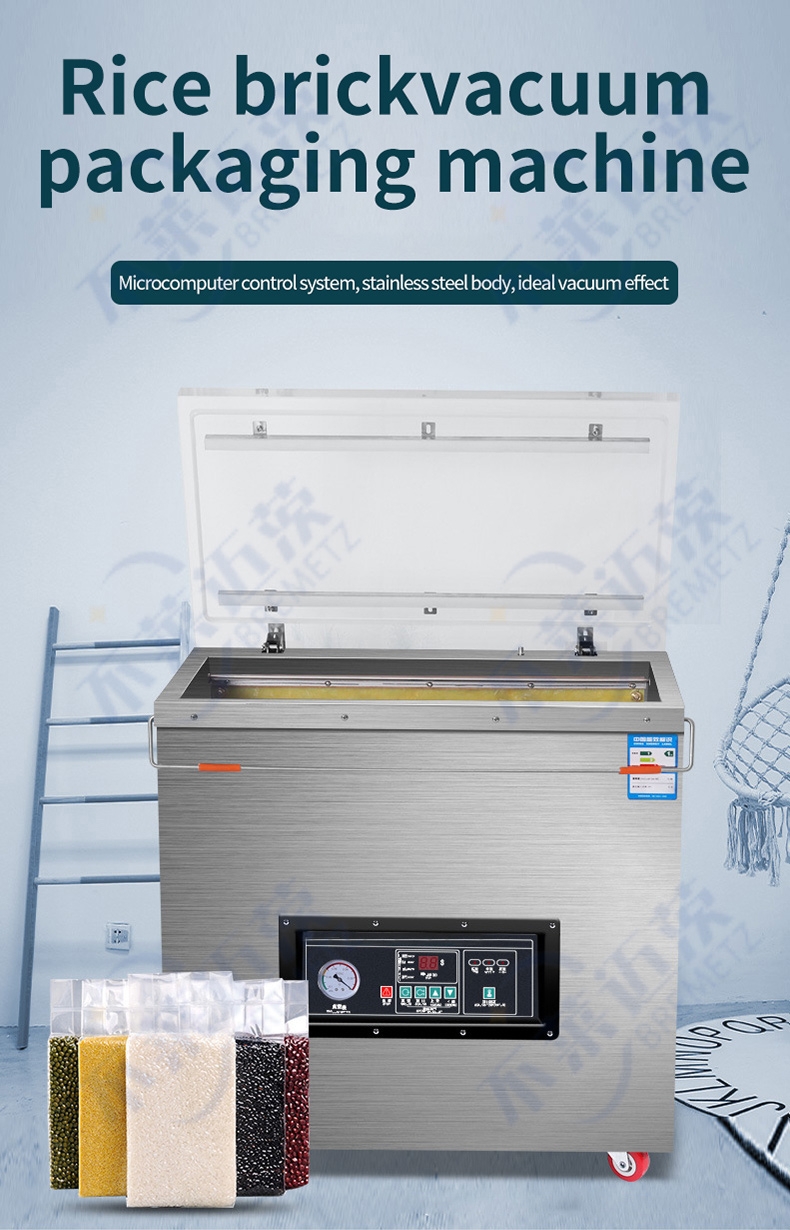

Brand name: Rice brick vacuum packaging machine

Overall dimensions (cm): 92*46*82

Vacuum pump Power (W): 900

Vacuum chamber(cm): 85*21*35

Rated voltage (V):220

Net weight(kg): 82

Degree of automation: Automatic all-in-one machine

Rated frequency: 50HZ

Sealing strip length: 85cm*2

Case material: Thickened stainless steel

Vacuum chamber max: 0.1mpa

Vacuum pump: 20L industrial pump

It has a set of precise material conveying mechanism, which can automatically feed, position and arrange the products according to their shape, size and packaging requirements.

By precisely controlling the sealing temperature, time and pressure, a firm and airtight sealing effect is achieved. The sealing is flat and smooth without any defects such as leakage, bubbles or wrinkles.

A simple and intuitive operation interface is designed, and operators only need simple training to master the operation methods and daily maintenance points of the equipment.