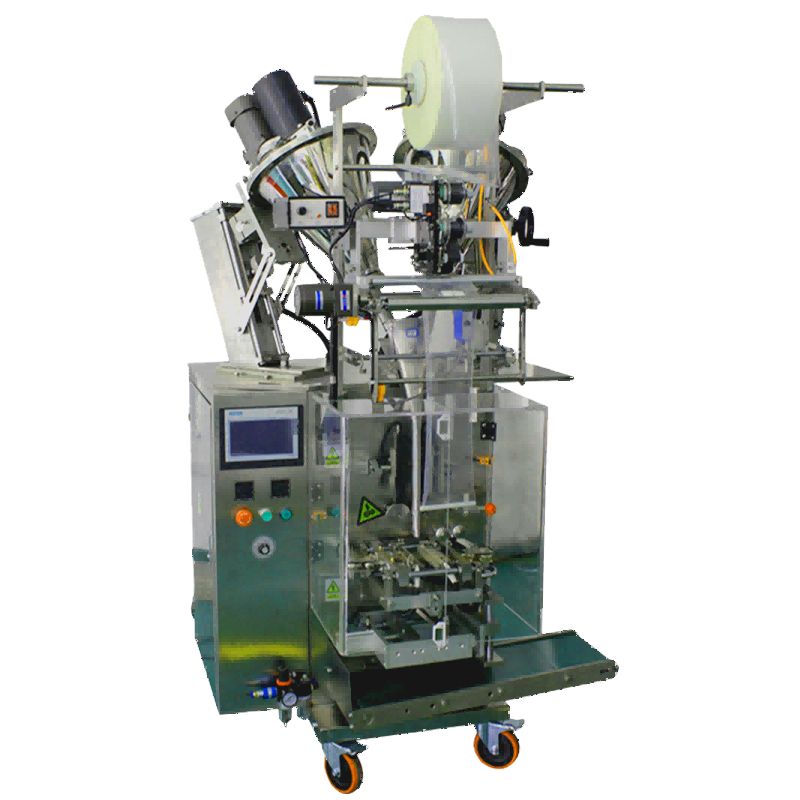

Double hopper powder automatic packaging machine

1. The two hoppers can work at the same time, and can alternately or collaboratively supply materials, reducing the waiting time for frequent feeding of a single hopper.

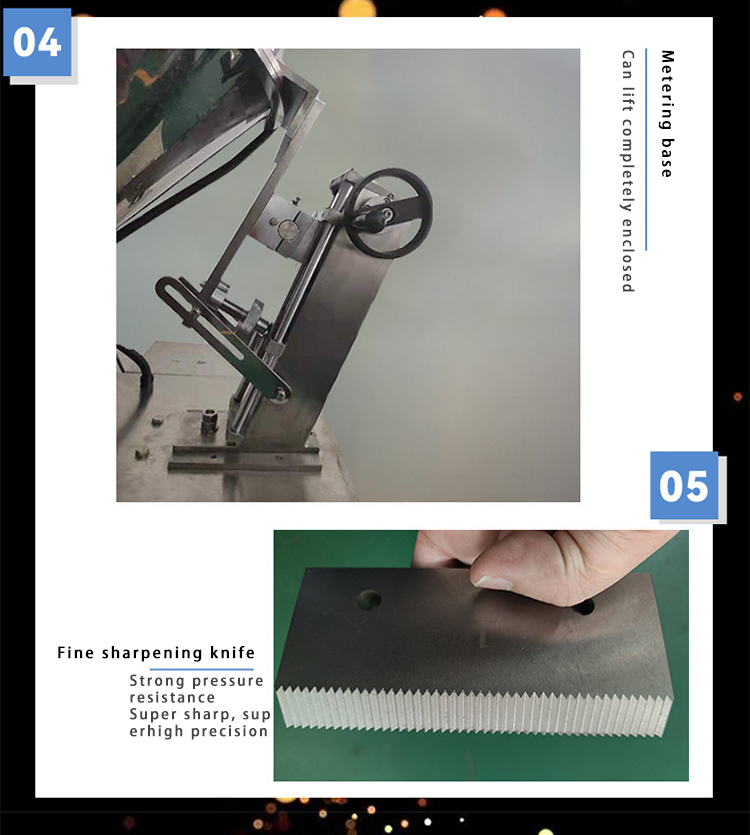

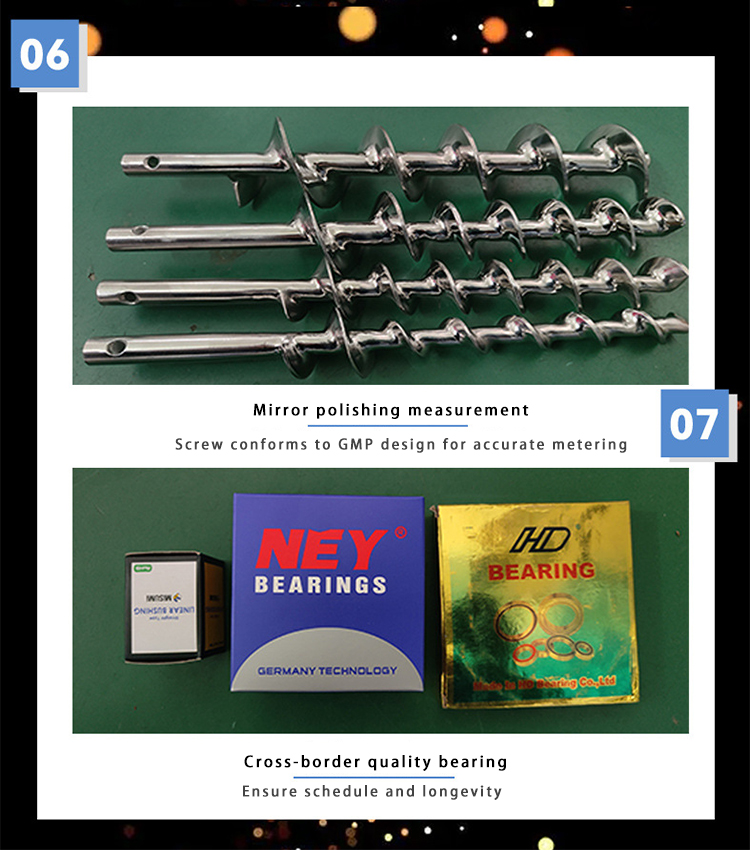

2. The use of advanced metering devices, such as spiral metering devices, weighing sensors, etc., can accurately measure powder materials.

3. The metering range is usually wide, and can be flexibly adjusted according to different packaging specifications and product requirements, and can adapt to powder packaging of various weight specifications.

4. For various powder materials of different properties, such as flour and milk powder with good fluidity, as well as powders with poor fluidity and easy to agglomerate, they can be effectively processed.

5. Equipped with special anti-blocking devices and stirring mechanisms, it can effectively prevent powder from agglomerating and clogging in the hopper or conveying pipeline.

The double-hopper automatic powder packaging machine is an advanced packaging equipment designed specifically for powder products. It is widely used in many industries such as food, medicine, and chemicals. With its unique double-hopper design and excellent automation performance, it provides an efficient, accurate and flexible solution for powder packaging.

The two hoppers can work independently at the same time, which can not only process the packaging tasks of two different powders in parallel to improve the overall packaging efficiency; but also can use the hoppers alternately according to production needs to achieve fast switching packaging of different powder products.

During the packaging process, the packaging material can be closely attached to the powder to form a firm and well-sealed package. Whether it is packaged in plastic film, paper bag or composite material, it can effectively prevent powder leakage, moisture, oxidation and other problems.

It has strong versatility and can adapt to the packaging needs of powders with different properties, particle sizes and fluidity. You only need to simply adjust the equipment parameters, such as the metering device range, vibration feeding amplitude, etc., to achieve precise packaging.

During the packaging design process, the utilization rate of packaging materials is fully considered. By optimizing the packaging process and control procedures, the amount of packaging materials used is accurately calculated to minimize waste.