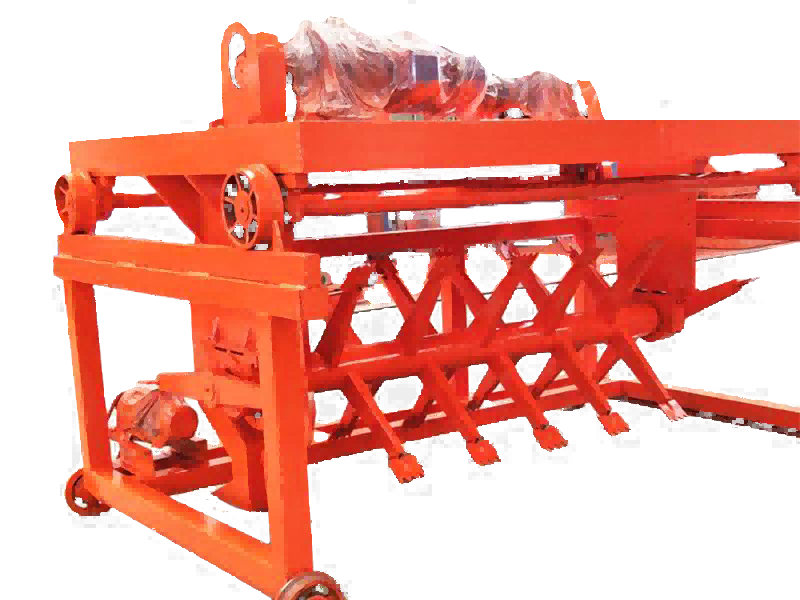

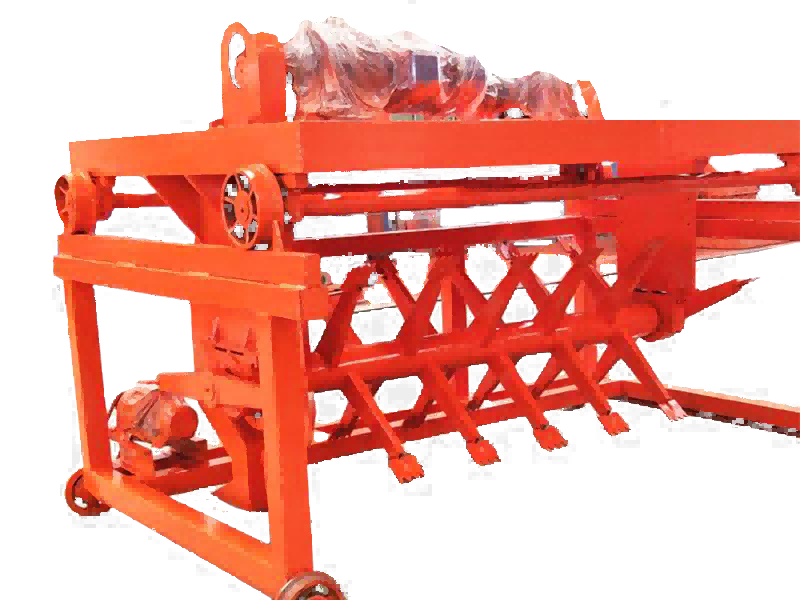

High speed trough type turning machine

1. The high-speed slot lathe has an extremely high spindle speed, which enables the tool to act on the workpiece quickly and significantly shortens the processing time.

2. The use of advanced ball screws and precision guide rails can accurately control the movement trajectory of the tool.

3. The slot structure design gives the lathe good rigidity and seismic resistance. It can effectively resist the vibration and deformation caused by cutting force.

4. It can process a variety of materials, including metal materials and non-metallic materials, to meet the processing needs of different industries for parts of different materials.

5. Equipped with an advanced CNC system with a friendly human-computer interaction interface, the operator can easily set the processing parameters through programming or manual input.

The high-speed spindle and fast moving speed greatly shorten the processing time and improve production efficiency. At the same time, the fast tool change system can complete the tool change in a short time, further improving the processing efficiency.

The use of advanced ball screws, precision guide rails and CNC systems ensures accurate movement and stable cutting of the tool, achieving high-precision processing.

The groove structure design gives the machine tool good rigidity and shock resistance, and can effectively resist vibration and deformation during high-speed cutting, ensuring the stability of the processing process and improving the stability of product quality.

It can process parts of various materials and shapes, has a wide range of applications, and can meet the diverse processing needs of different industries and different customers.

Equipped with advanced CNC system, it has a friendly human-computer interaction interface and is easy to operate. At the same time, the CNC system has functions such as fault diagnosis and automatic alarm, which facilitates the maintenance and management of the equipment.