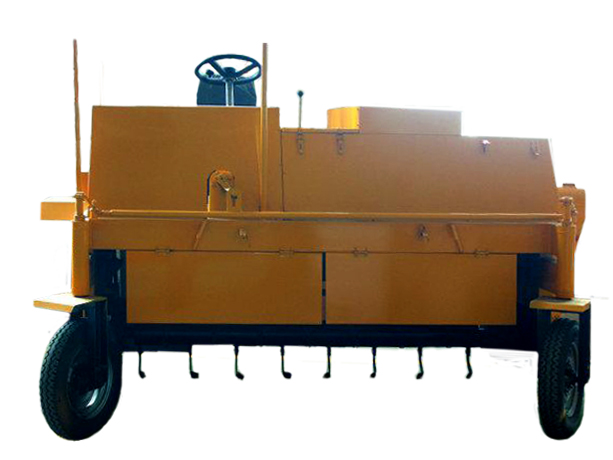

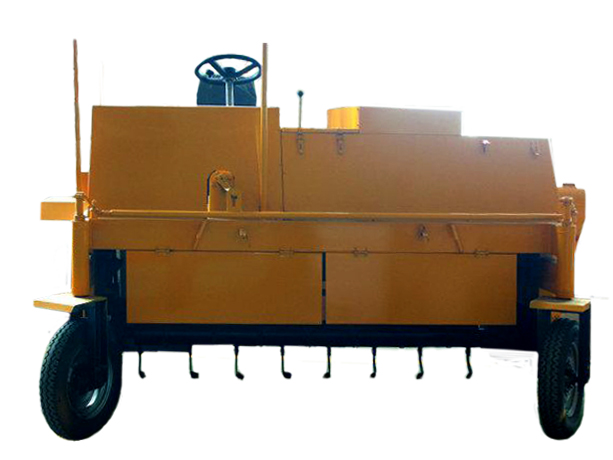

Fully automatic walking type turning machine

1. Simply place the workpiece to be processed at the designated position, set the processing parameters, and the machine can automatically complete the entire turning process.

2. It can run 24 hours a day, and the loading and unloading, cutting, and measuring processes are all completed automatically by the machine.

3. It can move freely between different workstations, and can flexibly adjust the processing position according to the needs of production layout and process flow.

4. Equipped with high-precision control systems and sensors, it can monitor and control various parameters in the processing process in real time to ensure that the processing accuracy can be stably controlled at a high level.

5. Using high-quality materials and advanced manufacturing technology, the bed structure is sturdy, the transmission system is stable, and the processing accuracy is guaranteed.

The fully automatic walking lathe is an advanced turning equipment that integrates automation, intelligence and flexibility. It breaks through the limitations of fixed-position processing of traditional lathes. Through its own walking function, it can move freely in the production workshop and realize efficient processing of workpieces at different workstations.

Equipped with advanced automatic tool changing device, different types of tools can be quickly and accurately replaced according to the requirements of the processing technology. The tool changing process is precisely controlled by the CNC system, and the tool changing time is short, which improves the processing efficiency. At the same time, it also ensures the accuracy and stability of tool replacement and ensures the processing quality.

With the advanced travel drive system, the lathe can travel autonomously on the preset track, and the travel speed can be adjusted according to actual processing requirements.With its walking function, the fully automatic walking lathe can flexibly switch between multiple workstations and continuously process different workpieces or different parts of the same workpiece.

The lathe bed, guide rails, screws and other key components are made of high-quality materials and advanced manufacturing processes, with high precision, high rigidity and good wear resistance. The precise mechanical structure ensures the stability of the lathe under high-speed operation and heavy cutting conditions, effectively reduces vibration and deformation during processing, and ensures that the processing accuracy can be controlled within a very small range.