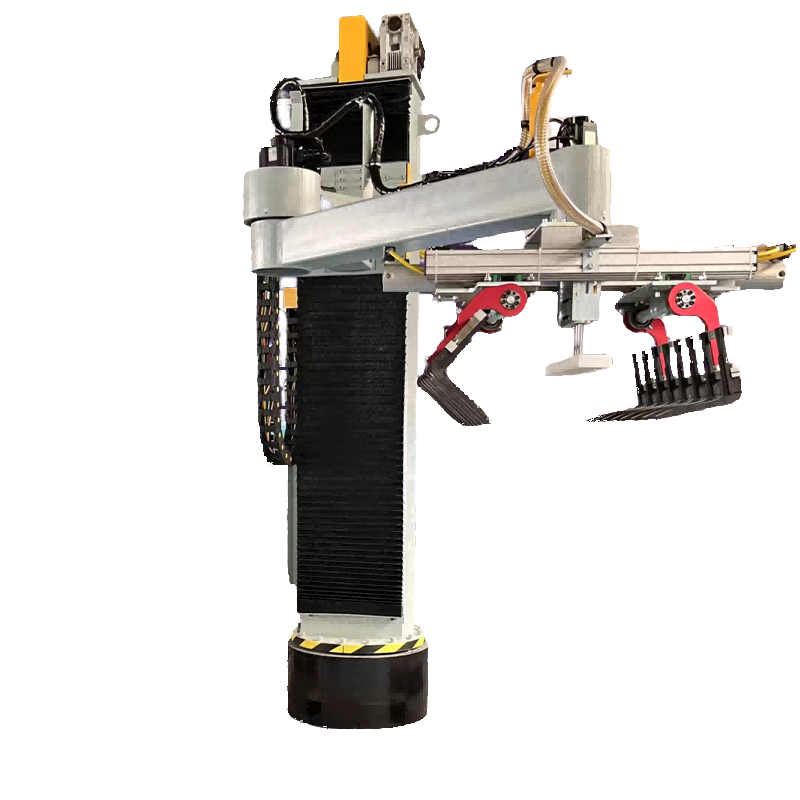

The structure of Multifunctional column robot

Column: As the supporting body of the robot, it usually has high strength and stability and can withstand various forces generated by the robot during movement.

Robotic arm: It is generally composed of multiple joints and connecting rods. The rotation of the joints is realized through driving devices such as servo motors, thereby driving the robotic arm to move flexibly in space and complete various operation tasks.

End effector: It is a component that directly contacts the work object and performs specific operations. According to different application scenarios, it can be equipped with various types of end effectors, such as grippers, suction cups, spray guns, welding heads, cutting tools, etc.

Control system: The control system usually includes components such as controllers, drivers, sensors, etc. Through programming and algorithms, the robot can automatically complete various complex actions according to different task requirements and ensure the accuracy and stability of the actions.

Transmission device: It is used to transmit power from the drive source to the various joints and components of the robot to realize the movement of the robotic arm. Common transmission methods include gear transmission, belt transmission, chain transmission, ball screw transmission, etc.