Technological innovation creates high efficiency slot lathe excellent quality

After years of hard work and countless tests, the company's R&D team has made a major breakthrough in the technology of efficient slot lathes. This lathe combines advanced mechanical design concepts and cutting-edge automation control technology, showing remarkable performance advantages.

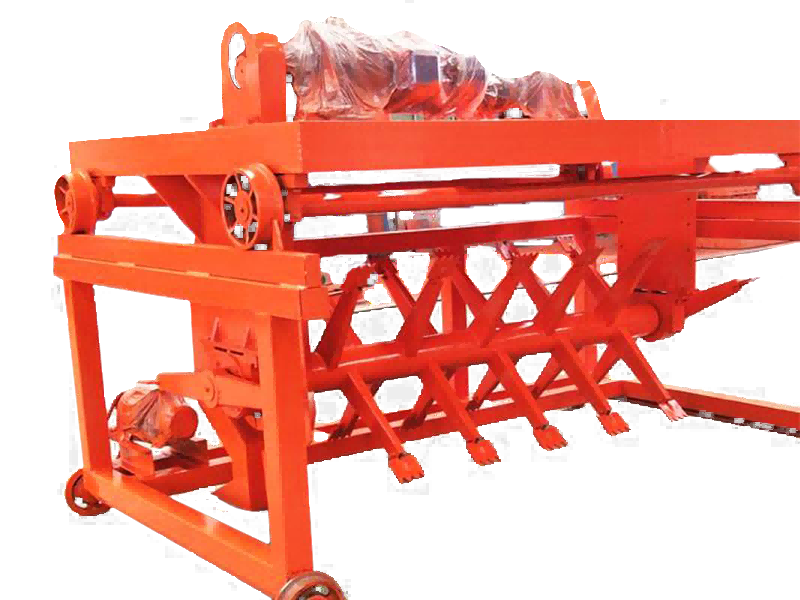

In terms of structural design, we have optimized the design of the bed and guide rails. The bed is made of high-strength and high-toughness alloy materials, and after a special heat treatment process, it effectively improves the overall rigidity and stability. The guide rail uses advanced linear guide technology, which has the characteristics of low friction and high load-bearing capacity, greatly improving the movement accuracy and cutting efficiency of the tool.

The cutting system is one of the core highlights of the efficient slot lathe. The new cutting tool we independently developed uses super-hard and wear-resistant materials and a unique cutting edge design. This tool can maintain a sharp cutting edge during the cutting process, greatly extending the service life of the tool, while also improving the cutting speed and processing quality.

In addition, the automated control system is another innovation of this lathe. It is equipped with an intelligent CNC system, and the operator can easily complete complex processing tasks by simply entering simple instructions on the operation panel. The system also has automatic monitoring and diagnosis functions, which can detect the operating status of the equipment in real time. Once an abnormal situation is detected, it will immediately issue an alarm and prompt a solution, effectively reducing equipment downtime and improving production efficiency and equipment reliability.